7 reasons to use plastisol ink for screen printing

By A Mystery Man Writer

Last updated 16 May 2024

Despite the many advancements in garment printing technology, plastisol ink screen printing remains the gold standard. While there are other great options

Our Rapid Cure Inks Cure as low as 270F for the best energy savings dye blocking scorching prevention and shrink prevention Creamy Bold Formula Plastisol Rapid Cure Inks have a High Opacity - Develop Color Quicker on the Press. Shades may vary due to the color and resolution of your computer screen and/or your particular color printer output. Buy Direct This ink works great and wont break the bank. Formulated and designed by printers for printers.

Rapid Cure White Screen Printing Ink (Pint - 16oz.) - Plastisol Ink for Screen Printing Fabric - Low Temperature Curing Plastisol by Screen Print

Screen Printing with Puff Ink: Weighing Pros vs. Cons - Screen

General Information about Screen Printing Plastisol Inks – Lawson

7 reasons to use plastisol ink for screen printing

Apparel Screen Printing Inks: Pros and Cons of Every

Our Rapid Cure Inks Cure as low as 270F for the best energy savings dye blocking scorching prevention and shrink prevention Creamy Bold Formula Plastisol Rapid Cure Inks have a High Opacity - Develop Color Quicker on the Press. Shades may vary due to the color and resolution of your computer screen and/or your particular color printer output. Buy Direct This ink works great and wont break the bank. Formulated and designed by printers for printers.

Rapid Cure Black Plastisol Ink for Screen Printing Low Temperature Fast Curing Ink by Screen Print Direct - Pint - 16 oz.

3 REASONS WHY PLASTISOL INK IS THE BEST SCREEN PRINTING INK – FN-INK

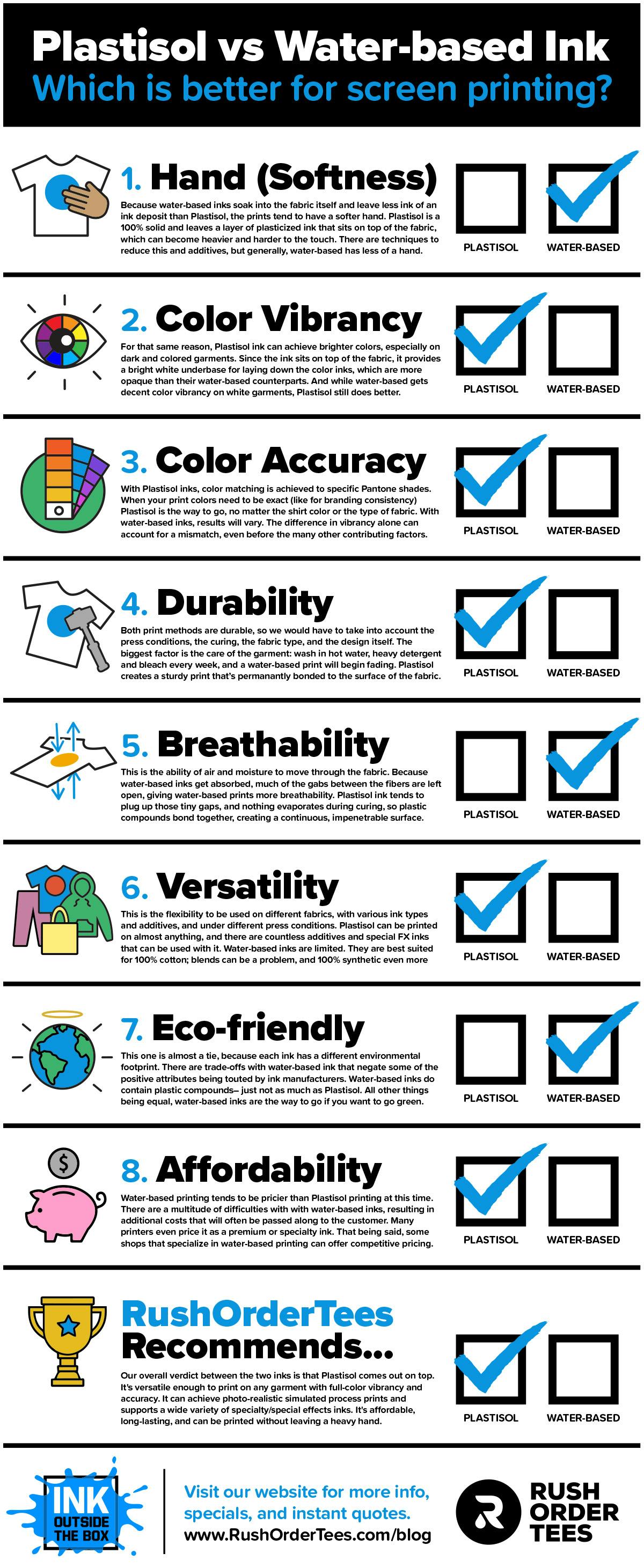

Screen Printing Ink Types Comparing Water-based & Plastisol

Triangle Screen Printing Ink - Hot Pink

The Difference Between Water-Based & Plastisol Inks

Our Rapid Cure Inks Cure as low as 270F for the best energy savings dye blocking scorching prevention and shrink prevention Creamy Bold Formula Plastisol Rapid Cure Inks have a High Opacity - Develop Color Quicker on the Press. Shades may vary due to the color and resolution of your computer screen and/or your particular color printer output. Buy Direct This ink works great and wont break the bank. Formulated and designed by printers for printers.

Screen Print Direct Rapid Curea Fluorescent Green Screen Printing Ink (8oz) - Plastisol Ink for Screen Printing Fabric - Low Temperature Curing Plas

Removes Plastisol Ink - Simply spray down your silk screen and our screen cleaner does the hard work. This spray dissolves screen printing ink quickly

Ecotex® Plastisol Screen Wash (Quart - 32oz.)- Use in Sink and Screen Printing Press - Degreaser and Degradant Cleaner for Screen Printing Inks - Silk

Recommended for you

-

Sericol Texopaque Plastisol Ink16 May 2024

Sericol Texopaque Plastisol Ink16 May 2024 -

BAIT PLASTICS PREMIUM PLASTISOL - 1 GALLON - Bait Plastics16 May 2024

BAIT PLASTICS PREMIUM PLASTISOL - 1 GALLON - Bait Plastics16 May 2024 -

Plastisol Ultimate Mixing System (UMX) - Gallon Kit16 May 2024

Plastisol Ultimate Mixing System (UMX) - Gallon Kit16 May 2024 -

Plastisol Heat Transfer Durability and Longevity — Howard Custom16 May 2024

Plastisol Heat Transfer Durability and Longevity — Howard Custom16 May 2024 -

Ecotex® Plastisol Ink Polyester White16 May 2024

Ecotex® Plastisol Ink Polyester White16 May 2024 -

Plastisol Transfer - Paper - Welcome to Florida Flexible Screen16 May 2024

Plastisol Transfer - Paper - Welcome to Florida Flexible Screen16 May 2024 -

What are plastisols and how are they made? - Oliver + Batlle16 May 2024

What are plastisols and how are they made? - Oliver + Batlle16 May 2024 -

Texsource TexBlack Plastisol Ink Texsource — Texsource Screen16 May 2024

Texsource TexBlack Plastisol Ink Texsource — Texsource Screen16 May 2024 -

TRIANGLE 1166 DARK BROWN PLASTISOL OIL BASE INK FOR SILK SCREEN PRINTING16 May 2024

TRIANGLE 1166 DARK BROWN PLASTISOL OIL BASE INK FOR SILK SCREEN PRINTING16 May 2024 -

Allureglow USA Black Plastisol Reflective Ink - Quart – Lee's Supply16 May 2024

Allureglow USA Black Plastisol Reflective Ink - Quart – Lee's Supply16 May 2024

You may also like

-

Embroidery Floss DMC Light Blue – Wee Scotty16 May 2024

Embroidery Floss DMC Light Blue – Wee Scotty16 May 2024 -

HuBorns - Baby Clay Handprint and Footprint Kit - Baby Shower16 May 2024

HuBorns - Baby Clay Handprint and Footprint Kit - Baby Shower16 May 2024 -

So Big Watercolor Set16 May 2024

So Big Watercolor Set16 May 2024 -

Eco Friendly Matte Empty 10oz 12oz Unique Luxury Round Glass Candle Container - China Candle Jar and Candle Bottle price16 May 2024

Eco Friendly Matte Empty 10oz 12oz Unique Luxury Round Glass Candle Container - China Candle Jar and Candle Bottle price16 May 2024 -

DMC 01 - White Tin, 6 Strand Embroidery Floss 100% Cotton 8.7 Yards Per Skein16 May 2024

DMC 01 - White Tin, 6 Strand Embroidery Floss 100% Cotton 8.7 Yards Per Skein16 May 2024 -

VEVOR Welding Blanket 8 ft. x 10 ft. Portable Fire Retardant Mat Fiberglass with Carry Bag, White16 May 2024

VEVOR Welding Blanket 8 ft. x 10 ft. Portable Fire Retardant Mat Fiberglass with Carry Bag, White16 May 2024 -

Queen Stuff Stickers Printable #stickers #printable #free #queen #stuff #gi… Scrapbook printables free, Scrapbook stickers printable, Scrapbooking stickers travel16 May 2024

Queen Stuff Stickers Printable #stickers #printable #free #queen #stuff #gi… Scrapbook printables free, Scrapbook stickers printable, Scrapbooking stickers travel16 May 2024 -

Velvet black simple wide bow hair ties Women droopy hair bow hair elas –16 May 2024

Velvet black simple wide bow hair ties Women droopy hair bow hair elas –16 May 2024 -

CoComelon Sticker Book Free Delivery – PoundFun™16 May 2024

CoComelon Sticker Book Free Delivery – PoundFun™16 May 2024 -

How to Make a Personalized Mug Using the Cricut Mug Press16 May 2024

How to Make a Personalized Mug Using the Cricut Mug Press16 May 2024