385CC UV Additive Powder – Fiberglass Source

By A Mystery Man Writer

Last updated 17 Jun 2024

Suggested 7cc of UV Powder per gallon of resin, adding more can result in faster cure but will result in a greenish-yellow final cured resin color,

Suggested 7cc of UV Powder per gallon of resin, adding more can result in faster cure but will result in a greenish-yellow final cured resin color. Thick laminates over 1/4" thick, pigment or logo laminates that may disrupt UV rays from fully penetrating the laminate may result in uncured areas. We suggest doing your own sample testing.The UV curing process requires a light source which directs UV or visible light onto the formulated product. Photoinitiators absorb the UV energy from the light source, setting in motion a chemical reaction that quickly, in fractions of a second, converts the liquid formulation into a solid, cured film.Methyl ethyl ketone peroxide also known as MEKP, catalyst or hardener, is a chemical that is added to polyester and vinyl resins to initiate a cured product. When MEKP is mixed with the resin, the resulting chemical reaction causes heat to build up and cure or harden the polyester resin. MEKP is required with all polyester resins, gel coats and vinyl ester resin.

Suggested 7cc of UV Powder per gallon of resin, adding more can result in faster cure but will result in a greenish-yellow final cured resin color. Thick laminates over 1/4 thick, pigment or logo laminates that may disrupt UV rays from fully penetrating the laminate may result in uncured areas. We suggest doing your own sample testing.The UV curing process requires a light source which directs UV or visible light onto the formulated product. Photoinitiators absorb the UV energy from the light source, setting in motion a chemical reaction that quickly, in fractions of a second, converts the liquid formulation into a solid, cured film.

Suggested 7cc of UV Powder per gallon of resin, adding more can result in faster cure but will result in a greenish-yellow final cured resin color. Thick laminates over 1/4 thick, pigment or logo laminates that may disrupt UV rays from fully penetrating the laminate may result in uncured areas. We suggest doing your own sample testing.The UV curing process requires a light source which directs UV or visible light onto the formulated product. Photoinitiators absorb the UV energy from the light source, setting in motion a chemical reaction that quickly, in fractions of a second, converts the liquid formulation into a solid, cured film. Methyl ethyl ketone peroxide also known as MEKP, catalyst or hardener, is a chemical that is added to polyester and vinyl resins to initiate a cured product. When MEKP is mixed with the resin, the resulting chemical reaction causes heat to build up and cure or harden the polyester resin. MEKP is required with all polyester resins, gel coats and vinyl ester resin.

Fiberglass composites materials supplier. Surfboard shaping tools and supplies. Wholesale pricing to the public.

Suggested 7cc of UV Powder per gallon of resin, adding more can result in faster cure but will result in a greenish-yellow final cured resin color. Thick laminates over 1/4" thick, pigment or logo laminates that may disrupt UV rays from fully penetrating the laminate may result in uncured areas. We suggest doing your own sample testing.The UV curing process requires a light source which directs UV or visible light onto the formulated product. Photoinitiators absorb the UV energy from the light source, setting in motion a chemical reaction that quickly, in fractions of a second, converts the liquid formulation into a solid, cured film.Methyl ethyl ketone peroxide also known as MEKP, catalyst or hardener, is a chemical that is added to polyester and vinyl resins to initiate a cured product. When MEKP is mixed with the resin, the resulting chemical reaction causes heat to build up and cure or harden the polyester resin. MEKP is required with all polyester resins, gel coats and vinyl ester resin.

Suggested 7cc of UV Powder per gallon of resin, adding more can result in faster cure but will result in a greenish-yellow final cured resin color. Thick laminates over 1/4 thick, pigment or logo laminates that may disrupt UV rays from fully penetrating the laminate may result in uncured areas. We suggest doing your own sample testing.The UV curing process requires a light source which directs UV or visible light onto the formulated product. Photoinitiators absorb the UV energy from the light source, setting in motion a chemical reaction that quickly, in fractions of a second, converts the liquid formulation into a solid, cured film.

Methyl ethyl ketone peroxide also known as MEKP, catalyst or hardener, is a chemical that is added to polyester and vinyl resins to initiate a cured product. When MEKP is mixed with the resin, the resulting chemical reaction causes heat to build up and cure or harden the polyester resin. MEKP is required with all polyester resins, gel coats and vinyl ester resin.

Suggested 7cc of UV Powder per gallon of resin, adding more can result in faster cure but will result in a greenish-yellow final cured resin color. Thick laminates over 1/4 thick, pigment or logo laminates that may disrupt UV rays from fully penetrating the laminate may result in uncured areas. We suggest doing your own sample testing.The UV curing process requires a light source which directs UV or visible light onto the formulated product. Photoinitiators absorb the UV energy from the light source, setting in motion a chemical reaction that quickly, in fractions of a second, converts the liquid formulation into a solid, cured film. Methyl ethyl ketone peroxide also known as MEKP, catalyst or hardener, is a chemical that is added to polyester and vinyl resins to initiate a cured product. When MEKP is mixed with the resin, the resulting chemical reaction causes heat to build up and cure or harden the polyester resin. MEKP is required with all polyester resins, gel coats and vinyl ester resin.

Fiberglass composites materials supplier. Surfboard shaping tools and supplies. Wholesale pricing to the public.

Best Selling Products – Page 3 – Fiberglass Source

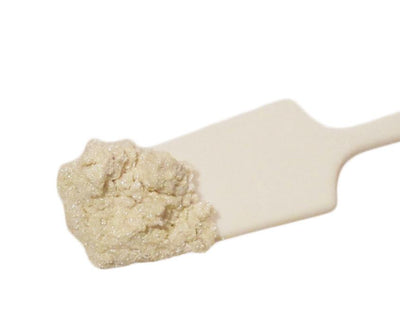

MP 30-36 Microtalc are particulates the size of 3 microns produced from an extensive deposit of high quality talc ore. Microtalc powder (magnesium

Microtalc MP 30-36 50 Lbs

Fiberglass Source Surfboard Building Supplies

Collections – Fiberglass Source

Epoxy Resin – Fiberglass Source

385CC UV Additive Powder – Fiberglass Source

Contains a blend of synthetic waxes and is one of FK’s premium mold release waxes.Proper application of this wax will result in a film that has high

1000P Hi-Low Paste Wax

385CC UV Additive Powder – Fiberglass Source

Texturing Additive Powder, Fine, Medium, Heavy

Best Selling Products – Page 3 – Fiberglass Source

Polyester Fiberglass Resin – Fiberglass Source

Epoxy Resin – Fiberglass Source

Vinyl Ester Resin – Fiberglass Source

Meguiar's Final Inspection M3416 1Gallon – Fiberglass Source

Recommended for you

-

Crushed Crystal Mica Powder Pigment (56g) Multipurpose DIY Arts and Crafts, Cosmetic Grade, Soap,Resin Epoxy,Paint, Slime, Mold Making, Candle17 Jun 2024

Crushed Crystal Mica Powder Pigment (56g) Multipurpose DIY Arts and Crafts, Cosmetic Grade, Soap,Resin Epoxy,Paint, Slime, Mold Making, Candle17 Jun 2024 -

DR CRAFTY Mica Powder for Epoxy Resin, Pigment Powder - Resin Mica Powder for Candle Making, Resin Powder – Epoxy Pigment Powder for Epoxy Resin, Mica17 Jun 2024

DR CRAFTY Mica Powder for Epoxy Resin, Pigment Powder - Resin Mica Powder for Candle Making, Resin Powder – Epoxy Pigment Powder for Epoxy Resin, Mica17 Jun 2024 -

Coldpac Ortho Resin Powder17 Jun 2024

Coldpac Ortho Resin Powder17 Jun 2024 -

Mica Powder Dyes and Colorants for Resin Art17 Jun 2024

Mica Powder Dyes and Colorants for Resin Art17 Jun 2024 -

Metallic Epoxy Pigments - 100 Colors Resin Powders - Mica Powder Jars — BALTIC DAY17 Jun 2024

Metallic Epoxy Pigments - 100 Colors Resin Powders - Mica Powder Jars — BALTIC DAY17 Jun 2024 -

Fertilizer Rubber Plastic Insulation Epoxy Resin Phenolic Resin Glass Reinforced Plastics Used Talcum Powder - China Talcum, Talcum Powder17 Jun 2024

Fertilizer Rubber Plastic Insulation Epoxy Resin Phenolic Resin Glass Reinforced Plastics Used Talcum Powder - China Talcum, Talcum Powder17 Jun 2024 -

Neutral Resin Powder Pigment - Collection Milk Coffee17 Jun 2024

Neutral Resin Powder Pigment - Collection Milk Coffee17 Jun 2024 -

Pearl powder for resin - pearlized resin powder, Resin Obsession17 Jun 2024

Pearl powder for resin - pearlized resin powder, Resin Obsession17 Jun 2024 -

Kean Best Seller Pet Resin Powder - China Pet, Polyethylene Terephthalate17 Jun 2024

Kean Best Seller Pet Resin Powder - China Pet, Polyethylene Terephthalate17 Jun 2024 -

Mica Powder for Resin Kit, 18 Colors17 Jun 2024

Mica Powder for Resin Kit, 18 Colors17 Jun 2024

You may also like

-

MELTING WAX CANDLES, Wax Melt Scents, Strong Scented Wax Melts Bar, Gifts for Women, Housewarming Gifts, Present for Mum,17 Jun 2024

MELTING WAX CANDLES, Wax Melt Scents, Strong Scented Wax Melts Bar, Gifts for Women, Housewarming Gifts, Present for Mum,17 Jun 2024 -

Mystery 101 Journal - Blank – Romance University17 Jun 2024

Mystery 101 Journal - Blank – Romance University17 Jun 2024 -

Crostio Baby Soft Crochet Yarn 2mm/2ply Thickness (Navy Blue) - Baby Soft Crochet Yarn 2mm/2ply Thickness (Navy Blue) . shop for Crostio products in India.17 Jun 2024

Crostio Baby Soft Crochet Yarn 2mm/2ply Thickness (Navy Blue) - Baby Soft Crochet Yarn 2mm/2ply Thickness (Navy Blue) . shop for Crostio products in India.17 Jun 2024 -

Ohuhu Art Brush Marker 24 Colors Set Brush Bold Type Comic Manga W/Blender Pen17 Jun 2024

Ohuhu Art Brush Marker 24 Colors Set Brush Bold Type Comic Manga W/Blender Pen17 Jun 2024 -

Metal Punk Rock Layered Chain Keychains For Men Women Waist - Temu17 Jun 2024

Metal Punk Rock Layered Chain Keychains For Men Women Waist - Temu17 Jun 2024 -

Granny Square Blocking Board, Wooden Blocking Board, Crochet Blocking Boards Set for Knitting and Crocheting, with Stainless Steel Rod Pins and Stand17 Jun 2024

Granny Square Blocking Board, Wooden Blocking Board, Crochet Blocking Boards Set for Knitting and Crocheting, with Stainless Steel Rod Pins and Stand17 Jun 2024 -

Clip Art Beveled Metal Alphabet Silver Metallic Letters Numbers17 Jun 2024

Clip Art Beveled Metal Alphabet Silver Metallic Letters Numbers17 Jun 2024 -

Gifts for quilters and sewers – Lou Orth Designs - Modern quilt17 Jun 2024

Gifts for quilters and sewers – Lou Orth Designs - Modern quilt17 Jun 2024 -

Gothic Border Stencil, 13 x 3 inch (L) - Medieval Architectural Wall Art Decor Stencils for Painting Template17 Jun 2024

Gothic Border Stencil, 13 x 3 inch (L) - Medieval Architectural Wall Art Decor Stencils for Painting Template17 Jun 2024 -

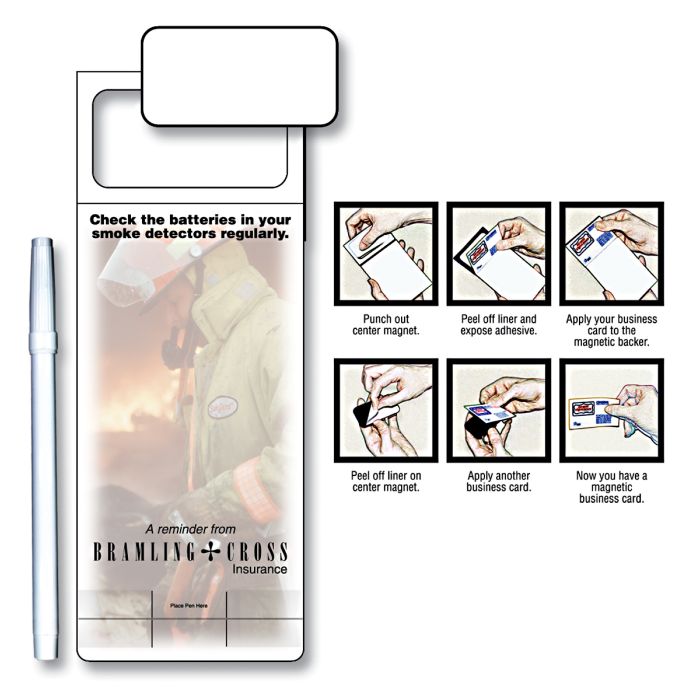

Peel Stick Magnet with Custom Card 3.5x917 Jun 2024

Peel Stick Magnet with Custom Card 3.5x917 Jun 2024