Differences Between Laser Marking, Laser Engraving and Laser

By A Mystery Man Writer

Last updated 29 May 2024

Our efficient systems feature advanced MOPA fiber lasers, ergonomic designs, and more designed for all of your laser engraving, laser marking, and laser etching needs.

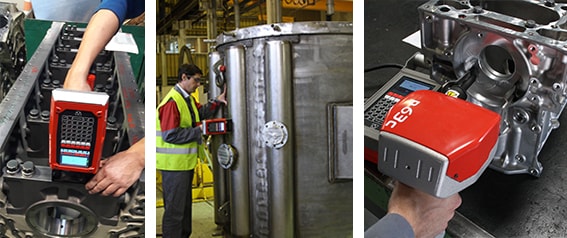

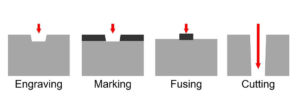

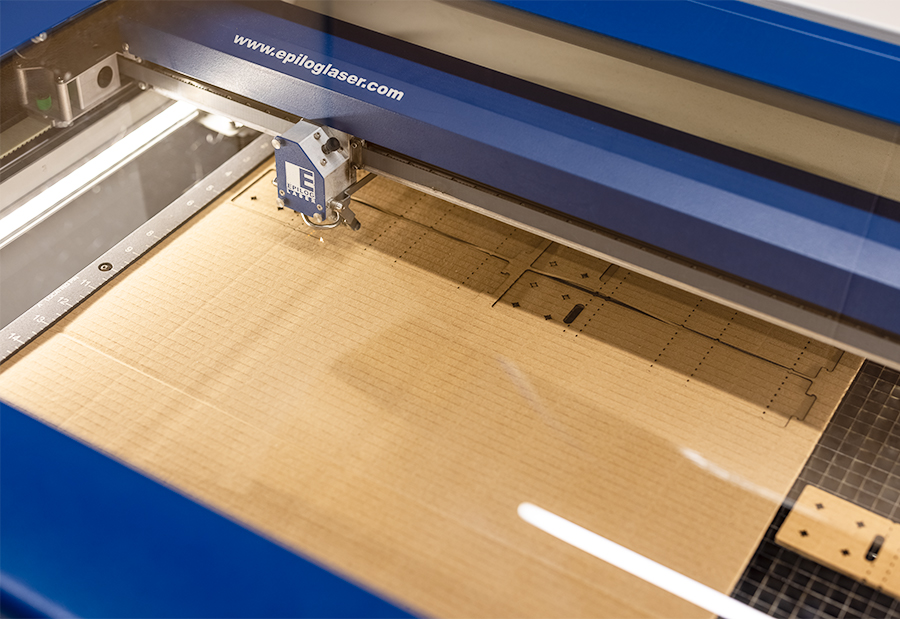

Thanks to industrial and government regulations regarding clearly legible product and part identification, the processes of laser marking, laser etching, and laser engraving are increasing in popularity. All three of these laser services provide permanent laser marking solutions, fulfilling regulations and adding distinction to your products and parts. But what sets them apart? While the three techniques may seem similar, there are actually quite a few differences between them. The differences between laser marking, laser engraving, and laser etching largely have to do with what each process does to the marking surface, including how deep the laser goes and how it changes the overall appearance. Laser marking discolors the surface of the material, while laser etching and engraving actually removes a portion of the surface area as it marks. The major difference between laser etching and laser engraving is the depth to which the laser penetrates the surface. Throughout this post, we will give you an overview of each of the processes and their applications to help you better determine which is right for your application needs. The Main Differences Between Laser Marking, Etching and Engraving Although these terms are often used interchangeably, there are differences between laser marking, laser etching, and laser engraving. Each type of process has its own applications and attributes that make it ideal for different jobs. Laser Marking, Etching and Engraving Demonstration TYKMA fiber laser systems are ideal for all types of laser marking, etching and engraving in a variety of materials and substrates. Exceed Your Production Expectations with a Laser Engraving System Request Information The Laser Marking Process Laser marking is what happens when the beam interacts with the surface of a material, slightly altering its properties or appearance. Some of the features of the laser marking process include the following: It is achieved by moving a low-powered beam slowly across the material using a method called discoloration, which creates high-contrast marks without disrupting the material Laser heats the material, causing oxidation under the surface and turning the material black It applies low temperatures to metal to anneal the surface All of this is done while leaving the surface intact Laser marking differs from laser engraving and laser etching in a number of ways, including the following: It is less common and not all places offer these services It is also referred to as laser coloration or laser dark marking, as well as charring for plastic materials and annealing for metals There are four common types of laser marking: annealing, carbon migration, foaming and coloration It’s popular in the medical device industry for stainless steel and titanium parts, but can be performed on other materials as well Laser marking is ideal for bar codes, UID codes, QR codes, logos and other identification needs The Laser Engraving Process Laser engraving is a process where the laser beam physically removes the surface of the material to expose a cavity that reveals an image at eye level. High heat is created during the laser engraving process, which essentially causes the material to vaporize It’s a quick process, as the material is vaporized with each pulse This creates a cavity in the surface that is noticeable to the eye and touch To form deeper marks with the laser engraving system, repeat with several passes Although laser engraving is a subsection of laser marking, it still differs in many ways: There are three types of laser engraving: etching, deep laser engraving, and laser ablation (the difference between the three is what the surface is and how much you remove) This is the most common option for people who want something personalized or customized Laser engraving is not ideal for marking safety critical parts The maximum engraving depth is 0.020 in metals but can go as deep as 0.125 in materials such as graphite This is the fastest way to mark with a laser It’s great for parts expected to experience high wear It’s typically used to laser engrave serial numbers and logos, among other things You can engrave on almost any kind of metal, plastic, wood, leather, and glass surface Another important comparison to make is how laser engraving compares to traditional engraving practices include: It can be done on a variety of materials It is more legible than traditional engraving for small objects, such as jewelry and watches It provides you with more font and style options There is a smaller chance of product damage or deformation over time Laser engraving machines are faster than traditional methods The Laser Etching Process Laser etching, which is a subset of laser engraving, occurs when the heat from the beam causes the surface of the material to melt. The laser beam uses high heat to melt the surface of the material The melted material expands and causes a raised mark Unlike laser engraving, the depth in laser etching is typically no more than 0.001” The differences between laser etching, marking and engraving include: Since a laser etcher changes the surface finish of metals, it alters its reflectivity and enhances contrast It removes 0.001 or less of the material It can be done on bare, anodized, or plated metal surfaces, as well as polymers and ceramics A Brief Overview of Lasers Let’s take a step back now and explain what exactly a laser is and how it works. “Laser” is actually an acronym that stands for Light Amplification by the Stimulated Emission of Radiation. Throughout the years, the laser has become one of the most powerful manufacturing tools a company can use. In order to create a laser, you raise the energy level of the atoms to an excited state, which enables them to release light as they fall back to their original energy, or ground state. But What Is a Laser Doing? If we look back at the second word in the acronym, amplification, we will gain a better understanding of what a laser does. Once this beam of light is created, it is amplified to produce a focal point. As the atoms begin to move, they create a weak light, and as more energy is added, the light waves become very concentrated. Unlike with other types of light (such as a flashlight), the light rays emitted from lasers all have the same wavelength and are coherent, which is what makes it such a powerful concentration of energy. Who Uses Lasers and Laser Engraving Systems? The laser is one of the most versatile modern inventions. Laser etching, marking, and engraving are used in almost every industry, including: Automotive General industrial Electronics Medical Military & defense Aerospace Products & goods Oil & gas and much more Each industry has its own uses for lasers. In the manufacturing industry, for example, laser marking systems are used in a variety of everyday tasks, such as welding, cutting, cleaning, measuring, drilling, and sensing, as well as marking, etching, and engraving. While there are other ways to mark materials, such as dot peen marking, they don’t give you the quality or environmentally friendly markings that you get with laser marking, laser etching, or laser engraving technologies. Why Does Your Business Need Laser Marking, Laser Etching and Laser Engraving? Whether you work in the automotive, aerospace, or medical device industry and you are working from a desk, you understand the importance of part identification. For each division of manufacturing, there are laws and regulations put in place regarding identification to reduce error and ensure part safety. What Are the Laws? In the medical device industry, the Food and Drug Administration released a final rule in 2013 requiring all manufacturers to include a unique device identifier (UDI) on device labels and packages, except where the rule provides for an exception or alternative; but as of September 2018, the FDA ruled that there must be visible dates on the labels of all devices, regardless if they are excepted from the 2013 rule. A UDI is a unique numeric or alphanumeric code that consists of two parts: a device identifier (DI) and a production identifier (PI). As of October 2022, the ruling is still in effect. The DI is a fixed portion that identifies the labeler and the version or model of the device, while the PI is used to identify several things, including the serial number, expiration date and the distinct identification code required for a human cell, tissue, or cellular and tissue-based product (HCT/P) regulated as a device. The notion of part traceability is similar to that utilized by automotive and aerospace part manufacturers. In the aerospace industry, engines, propellers and other replacement and modification parts are required to include certain registration and identification marking. The Federal Aviation Administration (FAA) determines which information is appropriate to include, such as the builder’s name, model designation and certification - if any - among other things. These markings are required to be on a fireproof dataplate or a similarly approved fireproof method. Why Is Part Traceability Important? Regulations for the medical device industry, the aerospace industry, and the automotive industry are designed to help increase safety for all types of parts. For example, automotive companies utilize part traceability to increase safety and reliability in their vehicles. If a component fails, the manufacturer can quickly and easily determine when and where the part was produced, allowing for critical recalls and warranty decisions to be made sooner. Industry-Leading Laser Marking, Engraving and Etching Machines from TYKMA Electrox At TYKMA Electrox, we provide our customers with the best technology, which is why we offer the most advanced laser marking, laser engraving and laser etching machines in the world. Our Master Oscillator Power Amplifier (MOPA) fiber laser technology has the capability to mark, engrave or etch on a variety of surfaces and materials, unlike other fiber laser marking systems that often have trouble processing some difficult or sensitive materials. Our machines allow you to easily engrave, mark or etch on materials ranging from gold and nickel plating to plastics and PCB. Other benefits of our MOPA laser-powered marking, engraving and etching machines include: Ten times more efficient than traditional YAG laser systems Available from 10 to 100 watts of power Maintenance-free design No lamps, water cooling or alignments Require no calibrations Longest reliability, with up to 100,000-hour lifespans and industry-leading warranties Compact machine with simple design Throughout the years, we’ve also expanded the capabilities of our machines to ensure that we can meet the diverse needs of the manufacturing industry. From our color and 3D marking capabilities to our systems designed to work with multiple devices, our constant innovation is what has set us apart from other laser engraving machine manufacturers. Contact Us Today to Learn More With our laser etching, laser engraving and laser marking systems, you can achieve the clear, high-quality marks your company needs. To learn more about our laser machines, and what they will accomplish for you, be sure to contact us and we’ll be happy to answer any questions you may have.

Thanks to industrial and government regulations regarding clearly legible product and part identification, the processes of laser marking, laser etching, and laser engraving are increasing in popularity. All three of these laser services provide permanent laser marking solutions, fulfilling regulations and adding distinction to your products and parts. But what sets them apart? While the three techniques may seem similar, there are actually quite a few differences between them. The differences between laser marking, laser engraving, and laser etching largely have to do with what each process does to the marking surface, including how deep the laser goes and how it changes the overall appearance. Laser marking discolors the surface of the material, while laser etching and engraving actually removes a portion of the surface area as it marks. The major difference between laser etching and laser engraving is the depth to which the laser penetrates the surface. Throughout this post, we will give you an overview of each of the processes and their applications to help you better determine which is right for your application needs. The Main Differences Between Laser Marking, Etching and Engraving Although these terms are often used interchangeably, there are differences between laser marking, laser etching, and laser engraving. Each type of process has its own applications and attributes that make it ideal for different jobs. Laser Marking, Etching and Engraving Demonstration TYKMA fiber laser systems are ideal for all types of laser marking, etching and engraving in a variety of materials and substrates. Exceed Your Production Expectations with a Laser Engraving System Request Information The Laser Marking Process Laser marking is what happens when the beam interacts with the surface of a material, slightly altering its properties or appearance. Some of the features of the laser marking process include the following: It is achieved by moving a low-powered beam slowly across the material using a method called discoloration, which creates high-contrast marks without disrupting the material Laser heats the material, causing oxidation under the surface and turning the material black It applies low temperatures to metal to anneal the surface All of this is done while leaving the surface intact Laser marking differs from laser engraving and laser etching in a number of ways, including the following: It is less common and not all places offer these services It is also referred to as laser coloration or laser dark marking, as well as charring for plastic materials and annealing for metals There are four common types of laser marking: annealing, carbon migration, foaming and coloration It’s popular in the medical device industry for stainless steel and titanium parts, but can be performed on other materials as well Laser marking is ideal for bar codes, UID codes, QR codes, logos and other identification needs The Laser Engraving Process Laser engraving is a process where the laser beam physically removes the surface of the material to expose a cavity that reveals an image at eye level. High heat is created during the laser engraving process, which essentially causes the material to vaporize It’s a quick process, as the material is vaporized with each pulse This creates a cavity in the surface that is noticeable to the eye and touch To form deeper marks with the laser engraving system, repeat with several passes Although laser engraving is a subsection of laser marking, it still differs in many ways: There are three types of laser engraving: etching, deep laser engraving, and laser ablation (the difference between the three is what the surface is and how much you remove) This is the most common option for people who want something personalized or customized Laser engraving is not ideal for marking safety critical parts The maximum engraving depth is 0.020 in metals but can go as deep as 0.125 in materials such as graphite This is the fastest way to mark with a laser It’s great for parts expected to experience high wear It’s typically used to laser engrave serial numbers and logos, among other things You can engrave on almost any kind of metal, plastic, wood, leather, and glass surface Another important comparison to make is how laser engraving compares to traditional engraving practices include: It can be done on a variety of materials It is more legible than traditional engraving for small objects, such as jewelry and watches It provides you with more font and style options There is a smaller chance of product damage or deformation over time Laser engraving machines are faster than traditional methods The Laser Etching Process Laser etching, which is a subset of laser engraving, occurs when the heat from the beam causes the surface of the material to melt. The laser beam uses high heat to melt the surface of the material The melted material expands and causes a raised mark Unlike laser engraving, the depth in laser etching is typically no more than 0.001” The differences between laser etching, marking and engraving include: Since a laser etcher changes the surface finish of metals, it alters its reflectivity and enhances contrast It removes 0.001 or less of the material It can be done on bare, anodized, or plated metal surfaces, as well as polymers and ceramics A Brief Overview of Lasers Let’s take a step back now and explain what exactly a laser is and how it works. “Laser” is actually an acronym that stands for Light Amplification by the Stimulated Emission of Radiation. Throughout the years, the laser has become one of the most powerful manufacturing tools a company can use. In order to create a laser, you raise the energy level of the atoms to an excited state, which enables them to release light as they fall back to their original energy, or ground state. But What Is a Laser Doing? If we look back at the second word in the acronym, amplification, we will gain a better understanding of what a laser does. Once this beam of light is created, it is amplified to produce a focal point. As the atoms begin to move, they create a weak light, and as more energy is added, the light waves become very concentrated. Unlike with other types of light (such as a flashlight), the light rays emitted from lasers all have the same wavelength and are coherent, which is what makes it such a powerful concentration of energy. Who Uses Lasers and Laser Engraving Systems? The laser is one of the most versatile modern inventions. Laser etching, marking, and engraving are used in almost every industry, including: Automotive General industrial Electronics Medical Military & defense Aerospace Products & goods Oil & gas and much more Each industry has its own uses for lasers. In the manufacturing industry, for example, laser marking systems are used in a variety of everyday tasks, such as welding, cutting, cleaning, measuring, drilling, and sensing, as well as marking, etching, and engraving. While there are other ways to mark materials, such as dot peen marking, they don’t give you the quality or environmentally friendly markings that you get with laser marking, laser etching, or laser engraving technologies. Why Does Your Business Need Laser Marking, Laser Etching and Laser Engraving? Whether you work in the automotive, aerospace, or medical device industry and you are working from a desk, you understand the importance of part identification. For each division of manufacturing, there are laws and regulations put in place regarding identification to reduce error and ensure part safety. What Are the Laws? In the medical device industry, the Food and Drug Administration released a final rule in 2013 requiring all manufacturers to include a unique device identifier (UDI) on device labels and packages, except where the rule provides for an exception or alternative; but as of September 2018, the FDA ruled that there must be visible dates on the labels of all devices, regardless if they are excepted from the 2013 rule. A UDI is a unique numeric or alphanumeric code that consists of two parts: a device identifier (DI) and a production identifier (PI). As of October 2022, the ruling is still in effect. The DI is a fixed portion that identifies the labeler and the version or model of the device, while the PI is used to identify several things, including the serial number, expiration date and the distinct identification code required for a human cell, tissue, or cellular and tissue-based product (HCT/P) regulated as a device. The notion of part traceability is similar to that utilized by automotive and aerospace part manufacturers. In the aerospace industry, engines, propellers and other replacement and modification parts are required to include certain registration and identification marking. The Federal Aviation Administration (FAA) determines which information is appropriate to include, such as the builder’s name, model designation and certification - if any - among other things. These markings are required to be on a fireproof dataplate or a similarly approved fireproof method. Why Is Part Traceability Important? Regulations for the medical device industry, the aerospace industry, and the automotive industry are designed to help increase safety for all types of parts. For example, automotive companies utilize part traceability to increase safety and reliability in their vehicles. If a component fails, the manufacturer can quickly and easily determine when and where the part was produced, allowing for critical recalls and warranty decisions to be made sooner. Industry-Leading Laser Marking, Engraving and Etching Machines from TYKMA Electrox At TYKMA Electrox, we provide our customers with the best technology, which is why we offer the most advanced laser marking, laser engraving and laser etching machines in the world. Our Master Oscillator Power Amplifier (MOPA) fiber laser technology has the capability to mark, engrave or etch on a variety of surfaces and materials, unlike other fiber laser marking systems that often have trouble processing some difficult or sensitive materials. Our machines allow you to easily engrave, mark or etch on materials ranging from gold and nickel plating to plastics and PCB. Other benefits of our MOPA laser-powered marking, engraving and etching machines include: Ten times more efficient than traditional YAG laser systems Available from 10 to 100 watts of power Maintenance-free design No lamps, water cooling or alignments Require no calibrations Longest reliability, with up to 100,000-hour lifespans and industry-leading warranties Compact machine with simple design Throughout the years, we’ve also expanded the capabilities of our machines to ensure that we can meet the diverse needs of the manufacturing industry. From our color and 3D marking capabilities to our systems designed to work with multiple devices, our constant innovation is what has set us apart from other laser engraving machine manufacturers. Contact Us Today to Learn More With our laser etching, laser engraving and laser marking systems, you can achieve the clear, high-quality marks your company needs. To learn more about our laser machines, and what they will accomplish for you, be sure to contact us and we’ll be happy to answer any questions you may have.

Laser Marking and Engraving Techniques

What are the differences between laser marking, laser engraving

HGLaser Online CO2 Laser Marking Machine (Marking On The Fly

Heavy Parts Marking Solutron Malaysia - Laser Marking and

Laser Etching Versus Laser Engraving

The difference between 2D laser and 3D laser engraving machine - blog

PDF) A comparison of Laser engraving machine,Laser marking machine

FINAL Year Presentation, PDF, Laser

What Are the Differences Between Laser Marking, Laser Engraving and Laser Etching • Universal Grinding Corporation

Deep Engraving Metal Fiber Laser Marking Machine 3D Laser Engraving Machine Price - China Fiber Laser Marking Machine, Laser Metal Engraving Machine

Recommended for you

-

LaserPecker 2 Laser Engraver, Laser Engraving Machine with Roller Portable Laser Cutter Compact Handheld Laser Etching Machine - with Storage29 May 2024

LaserPecker 2 Laser Engraver, Laser Engraving Machine with Roller Portable Laser Cutter Compact Handheld Laser Etching Machine - with Storage29 May 2024 -

Laser Engraver for Leather29 May 2024

Laser Engraver for Leather29 May 2024 -

DIY Mini CNC Laser Engraver. : 19 Steps (with Pictures29 May 2024

DIY Mini CNC Laser Engraver. : 19 Steps (with Pictures29 May 2024 -

Lazervida 10W Laser Cutter & Engraver by MatterHackers29 May 2024

-

Wainlux K8 Mini Laser Engraver review - an engraver anyone can29 May 2024

Wainlux K8 Mini Laser Engraver review - an engraver anyone can29 May 2024 -

Aufero AL2 Laser Engraving & Cutting Machine 15,000mm/min (5W/1.6W)29 May 2024

Aufero AL2 Laser Engraving & Cutting Machine 15,000mm/min (5W/1.6W)29 May 2024 -

The Ultimate Desktop Laser Engraver For Small Businesses In 2023!!29 May 2024

The Ultimate Desktop Laser Engraver For Small Businesses In 2023!!29 May 2024 -

1.6W Compact Laser Engraver Machine Portable Mini Desktop Laser29 May 2024

1.6W Compact Laser Engraver Machine Portable Mini Desktop Laser29 May 2024 -

Laser Etcher - Cutting - 900px - MSB Technology29 May 2024

Laser Etcher - Cutting - 900px - MSB Technology29 May 2024 -

MP6969-80 - 80W MOPA FIBER LASER MARKING ENGRAVING29 May 2024

MP6969-80 - 80W MOPA FIBER LASER MARKING ENGRAVING29 May 2024

You may also like

-

Deborah's Binding Tool Star Quilt (Quilting Land)29 May 2024

Deborah's Binding Tool Star Quilt (Quilting Land)29 May 2024 -

Ideas, Interior Architects, Whiteboard Paint, Dry Erase Paint, White Board Paint29 May 2024

Ideas, Interior Architects, Whiteboard Paint, Dry Erase Paint, White Board Paint29 May 2024 -

3m 4905 Double-Sided Tape 3mvhb Acrylic Foam Tape 3m High Temperature Resistant Red Film Sco Tch Tape - China 3m4910, 3m492029 May 2024

3m 4905 Double-Sided Tape 3mvhb Acrylic Foam Tape 3m High Temperature Resistant Red Film Sco Tch Tape - China 3m4910, 3m492029 May 2024 -

Wood Yarn Bowl Has It ALL Large Inlay Translucence &29 May 2024

Wood Yarn Bowl Has It ALL Large Inlay Translucence &29 May 2024 -

ChainMate 48 inch Survival Pocket Chain29 May 2024

ChainMate 48 inch Survival Pocket Chain29 May 2024 -

Acacia Wood Coasters for Drinks with Iron Holder Stand Set of 4, Wooden Coasters29 May 2024

Acacia Wood Coasters for Drinks with Iron Holder Stand Set of 4, Wooden Coasters29 May 2024 -

Natural Rose Petal Biodegradable Wedding Confetti. Dried Rose29 May 2024

Natural Rose Petal Biodegradable Wedding Confetti. Dried Rose29 May 2024 -

331-42 - Complete Set, 1908-09 Regular Issues, Set of 12 Stamps - Mystic Stamp Company29 May 2024

331-42 - Complete Set, 1908-09 Regular Issues, Set of 12 Stamps - Mystic Stamp Company29 May 2024 -

Custom Wedding Stickers Stickers For Your Big Day –29 May 2024

Custom Wedding Stickers Stickers For Your Big Day –29 May 2024 -

Silver Metallic Wired Ribbon29 May 2024

Silver Metallic Wired Ribbon29 May 2024