PURE TOUGH (SCRATCH&HEAT RESISTANT EPOXY COATING)

By A Mystery Man Writer

Last updated 07 Jun 2024

SDS PART A SDS PART B Healthofmindart epoxy systems are the most advanced on the Australian market , what separates and gives us a point of difference to our competitors is that we have been makers and we understand what makers want. Our products are 100% Australian made and we have the documents to back this up. Keep

Health of Mind Art proudly distributes top of the range art supplies, including our wonderful epoxy resin collection. Browse here.

SDS PART A SDS PART B Healthofmindart epoxy systems are the most advanced on the Australian market , what separates and gives us a point of difference to our competitors is that we have been makers and we understand what makers want. Our products are 100% Australian made and we have the documents to back this up. Keeping manufacturing in Australia is extremely important to us not only because we have some of the most rigorous quality control in the world but we help keep our economy going. When you buy our formulas not only are you getting the highest possible quality as we are one of 2 actual Australian made products, but you are helping grow our country and maintain it's high quality manufacturing standards. Our epoxies are high end formulas designed for long term results. It is extremely important our customers know that our products are designed for long term results. ALL epoxy resins contain aromatic rings which cause long term darkening, cheap epoxies will discolour extremely quickly. Our systems have the most “acceptable amounts” of UV stabilisers and absorbers. For a while Stonecoat the US company has provided a tough epoxy coating for benches etc, well we have worked seriously hard on this new scratch and super tough epoxy coating system. This epoxy would be one of the most durable, hard and scratch resistant epoxies in Australia. PURE TOUGH is a high gloss, low viscosity, self-levelling, solvent free two-pack coating designed as a hard-wearing top coat for timber, furniture, or art applications. PURE TOUGH achieves a high build in a single coat and provides an extremely durable, scratch resistant finish. Mix ratio: 2 parts A to 1 part B (vol) Work time: 15-30 minutes Film Thickness: 0.5 to 1mm per coat Coverage Rate: 0.5 to 1.0m2/L Recoat: 24-48hrs Light use: 36 hours Full Cure: 7 Days Colour Stability: Suitable for internal Shore D hardness: 75 VOC content: ≈0 g/L Application temperature: 10-35∞C heat resistant over 150 degrees do not apply butane torches , heat guns only Substrates should be thoroughly sanded or ground to provide a keyed surface. If applying over existing coatings, adhesion should be tested by preparation of a small test area. Remove all potential contaminants. Contact HOM if unsure. It is generally recommended that the surface to be coated be elevated from the work area to allow the coating to drip freely off the sides. Ensure tape and protective sheeting is used to protect work area. Ensure that the surface is level. PURE TOUGH is designed to be applied by pouring or spreading to achieve a high build. Apply via brush or spreader. Material can be applied thinly via roller however multiple coatings will be required to achieve the desired result. If bubbles occur, they can be easily broken via use of a heat gun – bubbles should be removed within 30 minutes of application. Some timber can have rejection issues with natural oils, so between coats wipe down with metho then sand, then wipe down with metho using fresh towels constantly . Multiple coats needs to applied . First coat will seal the timber as timber has a pouress nature to it. Sanding between coats and wiping with metho is required . Epoxies outside of Healthofmindart epoxies can have higher surfactants which can cause surface imperfections, wipe the surface with metho before re-coating . Available in 1.5L 3L AND 6L

Health of Mind Art proudly distributes top of the range art supplies, including our wonderful epoxy resin collection. Browse here.

SDS PART A SDS PART B Healthofmindart epoxy systems are the most advanced on the Australian market , what separates and gives us a point of difference to our competitors is that we have been makers and we understand what makers want. Our products are 100% Australian made and we have the documents to back this up. Keeping manufacturing in Australia is extremely important to us not only because we have some of the most rigorous quality control in the world but we help keep our economy going. When you buy our formulas not only are you getting the highest possible quality as we are one of 2 actual Australian made products, but you are helping grow our country and maintain it's high quality manufacturing standards. Our epoxies are high end formulas designed for long term results. It is extremely important our customers know that our products are designed for long term results. ALL epoxy resins contain aromatic rings which cause long term darkening, cheap epoxies will discolour extremely quickly. Our systems have the most “acceptable amounts” of UV stabilisers and absorbers. For a while Stonecoat the US company has provided a tough epoxy coating for benches etc, well we have worked seriously hard on this new scratch and super tough epoxy coating system. This epoxy would be one of the most durable, hard and scratch resistant epoxies in Australia. PURE TOUGH is a high gloss, low viscosity, self-levelling, solvent free two-pack coating designed as a hard-wearing top coat for timber, furniture, or art applications. PURE TOUGH achieves a high build in a single coat and provides an extremely durable, scratch resistant finish. Mix ratio: 2 parts A to 1 part B (vol) Work time: 15-30 minutes Film Thickness: 0.5 to 1mm per coat Coverage Rate: 0.5 to 1.0m2/L Recoat: 24-48hrs Light use: 36 hours Full Cure: 7 Days Colour Stability: Suitable for internal Shore D hardness: 75 VOC content: ≈0 g/L Application temperature: 10-35∞C heat resistant over 150 degrees do not apply butane torches , heat guns only Substrates should be thoroughly sanded or ground to provide a keyed surface. If applying over existing coatings, adhesion should be tested by preparation of a small test area. Remove all potential contaminants. Contact HOM if unsure. It is generally recommended that the surface to be coated be elevated from the work area to allow the coating to drip freely off the sides. Ensure tape and protective sheeting is used to protect work area. Ensure that the surface is level. PURE TOUGH is designed to be applied by pouring or spreading to achieve a high build. Apply via brush or spreader. Material can be applied thinly via roller however multiple coatings will be required to achieve the desired result. If bubbles occur, they can be easily broken via use of a heat gun – bubbles should be removed within 30 minutes of application. Some timber can have rejection issues with natural oils, so between coats wipe down with metho then sand, then wipe down with metho using fresh towels constantly . Multiple coats needs to applied . First coat will seal the timber as timber has a pouress nature to it. Sanding between coats and wiping with metho is required . Epoxies outside of Healthofmindart epoxies can have higher surfactants which can cause surface imperfections, wipe the surface with metho before re-coating . Available in 1.5L 3L AND 6L

HEAT PRO” Flexible Anti-Scratch Protective Resin – Resin Pro

Camphor laurel book matched pair 2707

Pure Tough (Scratch & Heat Resistant Epoxy Coating) – SPACE Cabinets

Architecture & Design July_August 2023 by Indesign Media Asia Pacific - Issuu

14 Best Kitchen Sink Materials for Ultimate Durability & Style – Vevano

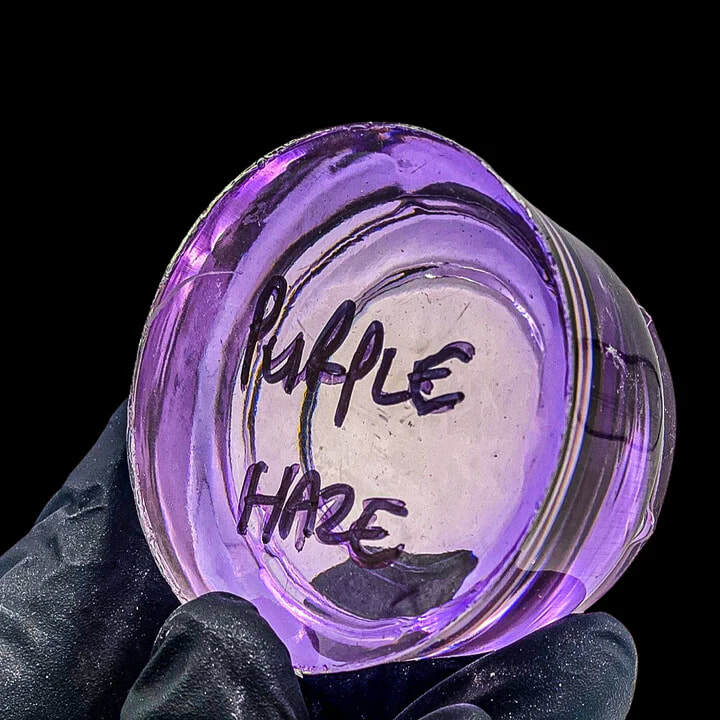

Translucent colour dyes designed for see through type castings and are suitable in most casting resins however have been designed and tested against

HOM Translucent Colour Dyes

Rockhard USA 100% Solids Epoxy

Superclear Deep Pour 24 Hour Premium Commercial Grade Epoxy Resin Kit, 1.5 Gallons - 2:1 Crystal Clear Liquid Glass Pouring up to 1 - Self-Leveling Food Safe Epoxy for Small to

Pure Tough (Scratch & Heat Resistant Epoxy Coating) – SPACE Cabinets

The Ultimate Material Comparison Guide, Pros & COns of Countertop Materials

SDS part A , SDS part B , 2k pure coat PU is a two component non-yellowing clear gloss finish acrylic modified polyurethane coating. This coating has

2k Pure Coat acrylic polyurethane

Countertops Archives - Page 2 of 3 - ICC Floors Plus Blog

Recommended for you

-

Let's Resin 1 Gallon Table Top Epoxy Resin Kit07 Jun 2024

Let's Resin 1 Gallon Table Top Epoxy Resin Kit07 Jun 2024 -

Permatex® 500° High Heat Epoxy, 25 ML – Permatex07 Jun 2024

Permatex® 500° High Heat Epoxy, 25 ML – Permatex07 Jun 2024 -

Pure Tough (Scratch & Heat Resistant Epoxy Coating) – SPACE Cabinets07 Jun 2024

Pure Tough (Scratch & Heat Resistant Epoxy Coating) – SPACE Cabinets07 Jun 2024 -

J-B Weld High Heat High Strength Acrylic Epoxy 0.85 oz07 Jun 2024

J-B Weld High Heat High Strength Acrylic Epoxy 0.85 oz07 Jun 2024 -

J-B Weld 8297 Epoxy Putty, High Heat, Gray, 2 oz.07 Jun 2024

J-B Weld 8297 Epoxy Putty, High Heat, Gray, 2 oz.07 Jun 2024 -

JB Weld High Heat Syringe 50197 - Advance Auto Parts07 Jun 2024

JB Weld High Heat Syringe 50197 - Advance Auto Parts07 Jun 2024 -

1pc Metal Repair Agent, High-strength Epoxy Resin Adhesive, Heat Resistant Industrial Repair Agent, Casting Ab Glue, Cast Iron Repairing Adhesive - Industrial & Commercial - Temu07 Jun 2024

1pc Metal Repair Agent, High-strength Epoxy Resin Adhesive, Heat Resistant Industrial Repair Agent, Casting Ab Glue, Cast Iron Repairing Adhesive - Industrial & Commercial - Temu07 Jun 2024 -

Heat Resistant Adhesive07 Jun 2024

Heat Resistant Adhesive07 Jun 2024 -

Epoxy Countertop Durability Test. WOW!07 Jun 2024

Epoxy Countertop Durability Test. WOW!07 Jun 2024 -

EB-119SP: Heat-Resistant Epoxy with Cure Indicator07 Jun 2024

EB-119SP: Heat-Resistant Epoxy with Cure Indicator07 Jun 2024

You may also like

-

Beoccudo Tackle Box Bead Organizer 2 Pack Fishing Tackle Box Organizer Plastic Compartment Storage Box Container with Dividers (Clear Tacklebox)07 Jun 2024

Beoccudo Tackle Box Bead Organizer 2 Pack Fishing Tackle Box Organizer Plastic Compartment Storage Box Container with Dividers (Clear Tacklebox)07 Jun 2024 -

Gear Aid Tenacious Repair Tape Clear07 Jun 2024

Gear Aid Tenacious Repair Tape Clear07 Jun 2024 -

Knitter's Pride Dreamz Interchangable Needle Cord – Monarch Knitting07 Jun 2024

Knitter's Pride Dreamz Interchangable Needle Cord – Monarch Knitting07 Jun 2024 -

5 Cubic Feet Chest Freezer w/ 7-Grade Adjustable Temperature for Kitchen White07 Jun 2024

5 Cubic Feet Chest Freezer w/ 7-Grade Adjustable Temperature for Kitchen White07 Jun 2024 -

Full Size Cordless Glue Gun, GoGonova 20V Temp Adjust LCD Digital Display Fast Heating Accurate Dual Temp, Dripless Full Size Heavy Duty Hot Gun Kit07 Jun 2024

Full Size Cordless Glue Gun, GoGonova 20V Temp Adjust LCD Digital Display Fast Heating Accurate Dual Temp, Dripless Full Size Heavy Duty Hot Gun Kit07 Jun 2024 -

Hole Puncher, Hole Punch, Circle Punch, Paper Punches For Crafting, Circle Hole Punch, 1 Inch Hole Punch, 1 Inch Circle07 Jun 2024

Hole Puncher, Hole Punch, Circle Punch, Paper Punches For Crafting, Circle Hole Punch, 1 Inch Hole Punch, 1 Inch Circle07 Jun 2024 -

C-Line Peel and Stick Dry Erase Sheets, 8 1/2 x 11, White, 2507 Jun 2024

C-Line Peel and Stick Dry Erase Sheets, 8 1/2 x 11, White, 2507 Jun 2024 -

26,620 Lime Outline Images, Stock Photos, 3D objects, & Vectors07 Jun 2024

26,620 Lime Outline Images, Stock Photos, 3D objects, & Vectors07 Jun 2024 -

How Is Dirt Made? – Mother Earth News07 Jun 2024

How Is Dirt Made? – Mother Earth News07 Jun 2024 -

Hyacinth Orange HotFix Rhinestones Iron On Flatback Gem Strass Glass Stone For Luxury Dress Glitter Decoration Design07 Jun 2024

Hyacinth Orange HotFix Rhinestones Iron On Flatback Gem Strass Glass Stone For Luxury Dress Glitter Decoration Design07 Jun 2024