Sheet Metal Hemming, Hem Types & Processes Explained

By A Mystery Man Writer

Last updated 04 Jun 2024

Hemming is a sheet metal forming process where the edge is folded onto itself. Hems make a part more durable and improve its appearance.

Die hemming carried out in 2 steps, manual flattening on a press brake

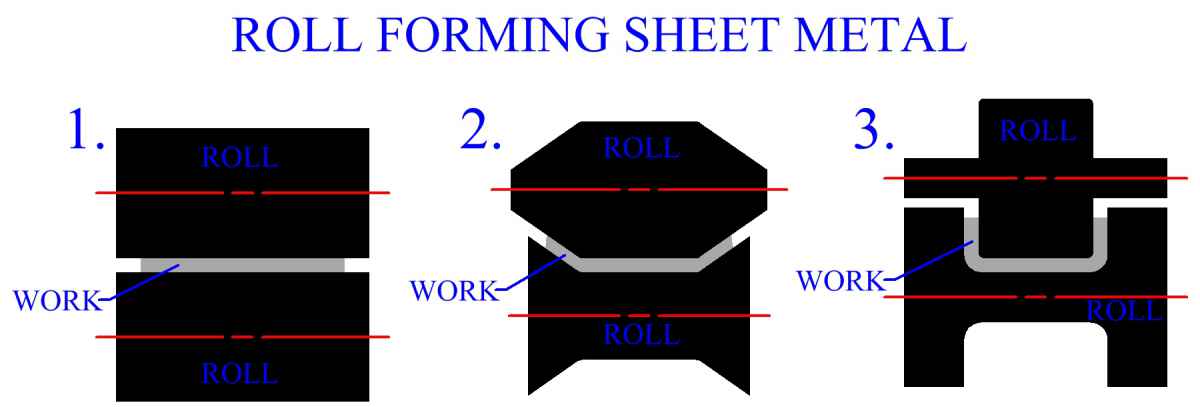

Hem roll die set, 3 rollers

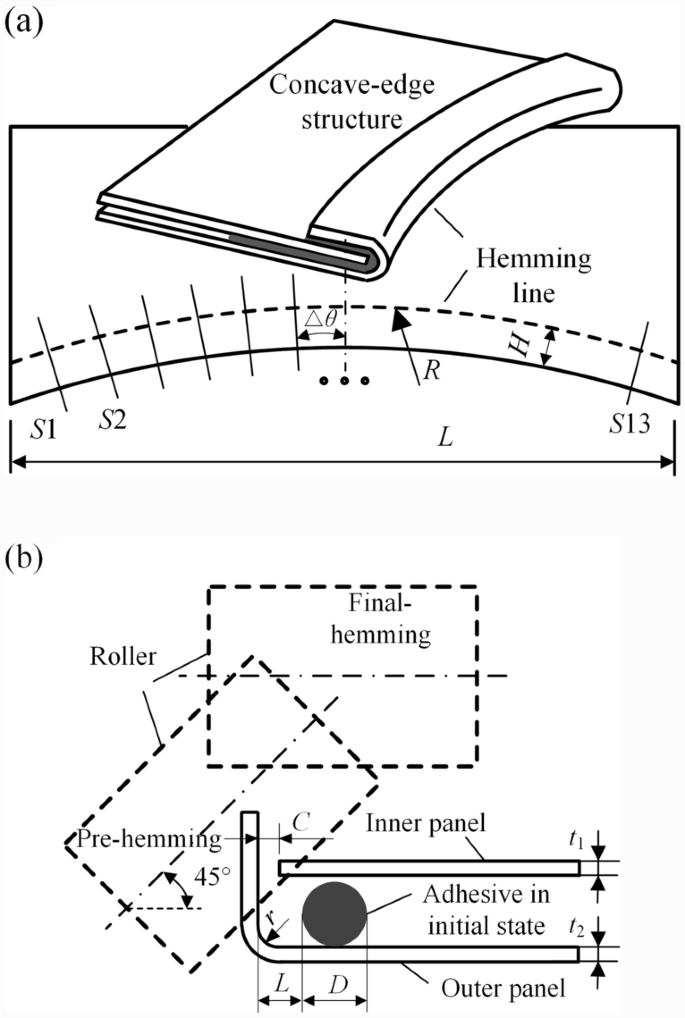

Roller Hemming offers high flexibility, automotive parts.

Die hemming carried out in 2 steps, manual flattening on a press brake

Hem roll die set, 3 rollers

Roller Hemming offers high flexibility, automotive parts.

Sheet Metal Fabrication: An introduction to the sheet metal designing

Sheet Metal Hemming Explained and Its Types - WayKen

Sheet Metal Bending

Sheet Metal Hemming Explained and Its Types - WayKen

Numerical Quantification Model and Experiment of External Force on Roller Hemming of Curved Edge Aluminium Alloy with Adhesive, Chinese Journal of Mechanical Engineering

Cross-sectional view after conventional hemming (roll-in: 1.04 mm; hem

A study on sheet metal hemming process - ScienceDirect

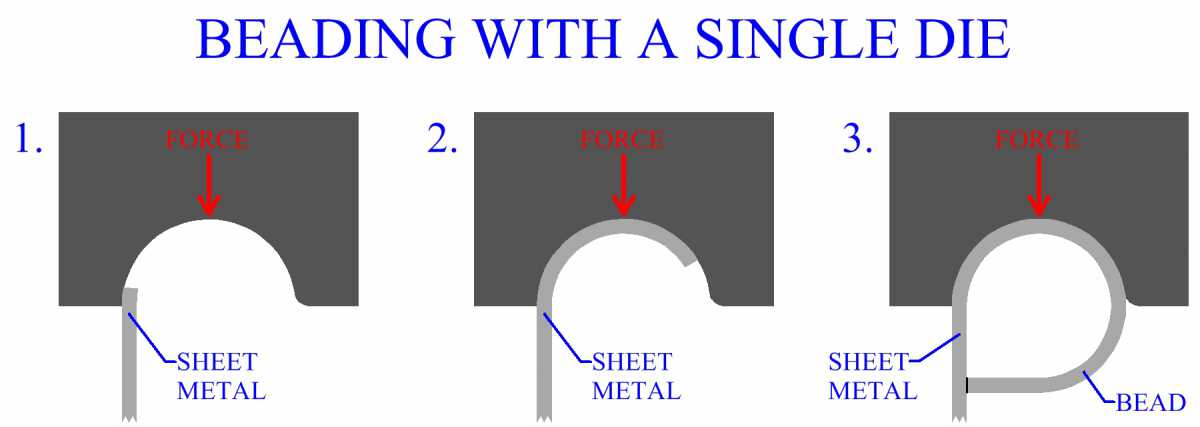

Sheet Metal Bending

Hem Bends

Recommended for you

-

Metal Panel Hemming Tool04 Jun 2024

Metal Panel Hemming Tool04 Jun 2024 -

Hemming Tool 24 for Metal Roof Panels Buy Metal Roofing Tools04 Jun 2024

Hemming Tool 24 for Metal Roof Panels Buy Metal Roofing Tools04 Jun 2024 -

Sheet Metal Hemming Tool For Metal Roof Panels04 Jun 2024

Sheet Metal Hemming Tool For Metal Roof Panels04 Jun 2024 -

Ciieeo Ring Hemming Device Swing Bracket Flat Seam Folder Binding bias Binder Foot Sewing Machine Binder Hemming Tool Sewing Machine Supply Curve04 Jun 2024

Ciieeo Ring Hemming Device Swing Bracket Flat Seam Folder Binding bias Binder Foot Sewing Machine Binder Hemming Tool Sewing Machine Supply Curve04 Jun 2024 -

20 Hemming Tool – Best Buy Metals04 Jun 2024

20 Hemming Tool – Best Buy Metals04 Jun 2024 -

Aluminum collision tools, OTC 501-080 Crimping Tool, Door Hem Flange04 Jun 2024

-

Robotergeführt Rollfalzen – EN – EngRoTec-Solutions GmbH04 Jun 2024

Robotergeführt Rollfalzen – EN – EngRoTec-Solutions GmbH04 Jun 2024 -

Stortz XL Bend Hem Combo - Stortz & Son Inc.04 Jun 2024

Stortz XL Bend Hem Combo - Stortz & Son Inc.04 Jun 2024 -

3D Printed Sewing Tool for Hems : 5 Steps - Instructables04 Jun 2024

3D Printed Sewing Tool for Hems : 5 Steps - Instructables04 Jun 2024 -

Malco Products DHT1 Malco TurboXTools DH Door Hemming Attachments04 Jun 2024

Malco Products DHT1 Malco TurboXTools DH Door Hemming Attachments04 Jun 2024

You may also like

-

hapray Magic Water Paint Coloring Books for Toddler, Art Toys Age 2-4, Educational Learning Doodle Toy, Gifts for Girl Boy 3 2 1+ Year (Dinosaur04 Jun 2024

hapray Magic Water Paint Coloring Books for Toddler, Art Toys Age 2-4, Educational Learning Doodle Toy, Gifts for Girl Boy 3 2 1+ Year (Dinosaur04 Jun 2024 -

3D DIY Solar System Model Kit Science Project Kids Educations Toy Birthday Gift04 Jun 2024

3D DIY Solar System Model Kit Science Project Kids Educations Toy Birthday Gift04 Jun 2024 -

Mani of the month stickers – Unicorn Smiles04 Jun 2024

Mani of the month stickers – Unicorn Smiles04 Jun 2024 -

IFWELL Collapsible Bucket with Handle 5 Gallon Portable Folding Bucket Upgrad04 Jun 2024

IFWELL Collapsible Bucket with Handle 5 Gallon Portable Folding Bucket Upgrad04 Jun 2024 -

Gentle Dose Petite Vaginal Applicator04 Jun 2024

Gentle Dose Petite Vaginal Applicator04 Jun 2024 -

Sleep and Beyond myMerino Wool Comforter Light04 Jun 2024

Sleep and Beyond myMerino Wool Comforter Light04 Jun 2024 -

Angelus Metallic Leather Paint - Montana Leather Company04 Jun 2024

Angelus Metallic Leather Paint - Montana Leather Company04 Jun 2024 -

Candle Dust Cover Template, Editable Candle Dust Covers, Printable04 Jun 2024

Candle Dust Cover Template, Editable Candle Dust Covers, Printable04 Jun 2024 -

Metal Ring Sizer04 Jun 2024

Metal Ring Sizer04 Jun 2024 -

Gridfinity wire spool holder by Kelly Egan, Download free STL model04 Jun 2024

Gridfinity wire spool holder by Kelly Egan, Download free STL model04 Jun 2024