Polymers, Free Full-Text

By A Mystery Man Writer

Last updated 29 May 2024

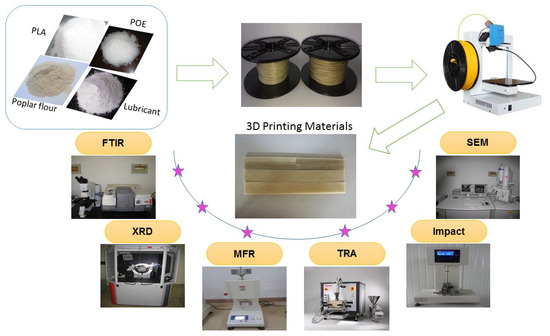

Three dimensional (3D) printing materials were manufactured with polylactic acid (PLA) and poplar powder using the twin screw extruder and 3D printing consumables extruder. Lubricant (TPW604) and toughening agent polyolefin elastomer (POE) were utilized to improve the fluidity and toughness of the materials. 3D printing materials were tested by infrared spectroscopy, X-ray diffraction, melt flow rate, rheology behavior, impact and scanning electron microscope. The results show that the poplar powder could decrease impact strength of PLA, the same as TPW604. Unlike poplar powder, TPW604 can improve the fluidity of 3D printing materials. And POE can fill the voids formed by poplar powder in PLA, enhance interface compatibility between poplar powder and PLA, and effectively improve the fluidity and impact strength of 3D printing materials.

Polymer Blends: Journal of Macromolecular Science, Part C: Vol 18, No 1

Review of chemo‐responsive shape change/memory polymers, scp 0079

Polymers, Free Full-Text

Polymers, Free Full-Text, códigos de double xp no block street

Polymers, Free Full-Text

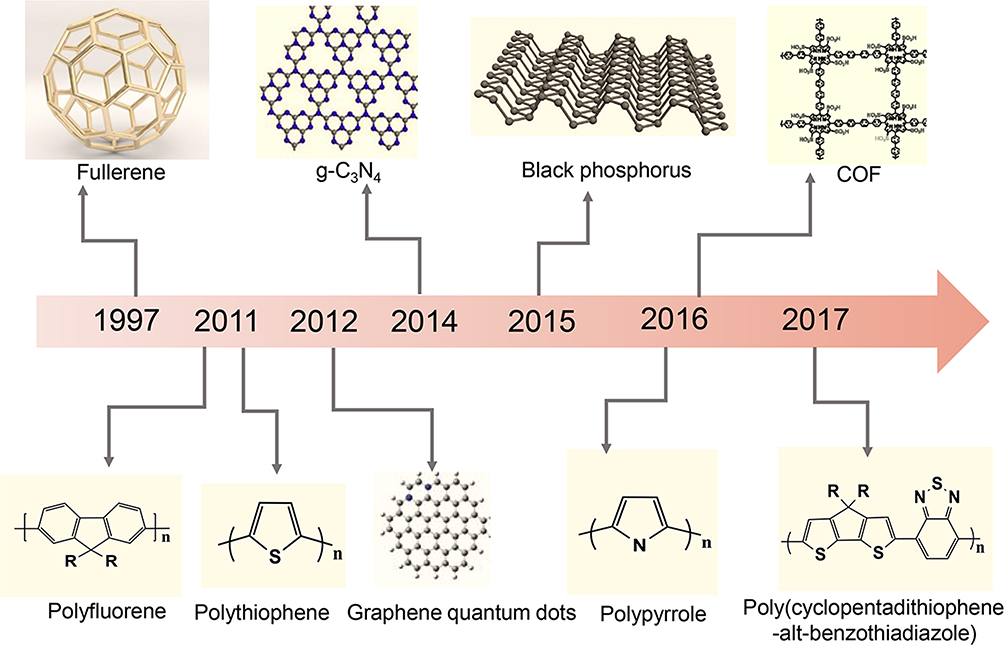

Strategies to Improve Photodynamic Therapy Efficacy of Metal-Free Semi

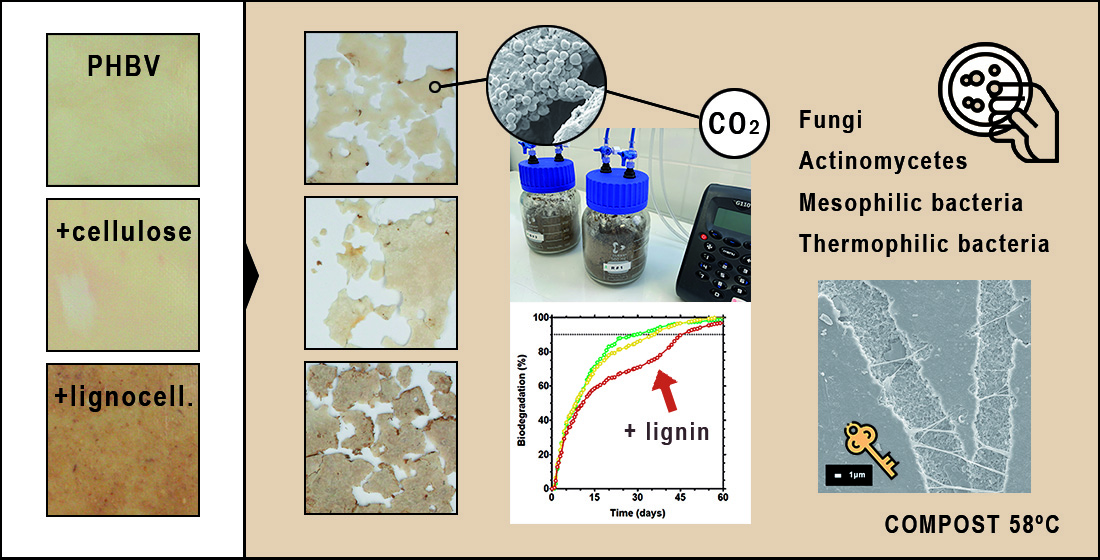

how will you prepare phbv polymer? –

PDF) Thermoresponsive Polymers In Liquid Chromatography, 56% OFF

Polymers Free Full Text Chemical Design Of Functional Polymer

Polymers, Free Full-Text

Polymers, Free Full-Text

Recommended for you

-

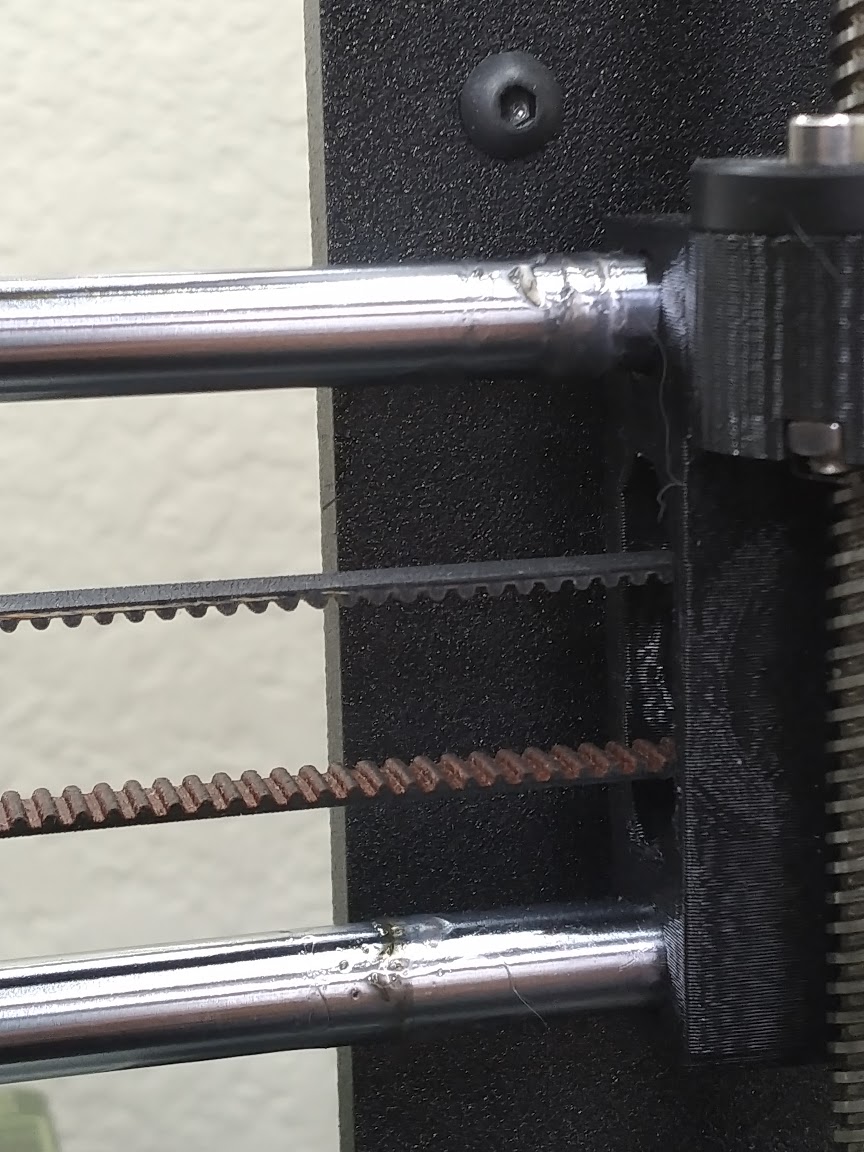

How to Lubricate Your 3d Printer (The Simple Way)29 May 2024

How to Lubricate Your 3d Printer (The Simple Way)29 May 2024 -

PlanetSafe AIM 3D Printer and CNC Machine Lubricant Oil - Extreme29 May 2024

PlanetSafe AIM 3D Printer and CNC Machine Lubricant Oil - Extreme29 May 2024 -

STL file CHAIN LUBE MOTO / CHAIN LUBE CHAIN CLEANER GREASE29 May 2024

STL file CHAIN LUBE MOTO / CHAIN LUBE CHAIN CLEANER GREASE29 May 2024 -

2pcs Super Lube Lubricating Grease Lubricant Oil -rust Screw Rod29 May 2024

2pcs Super Lube Lubricating Grease Lubricant Oil -rust Screw Rod29 May 2024 -

Industrial Lubricants, Grease 3d Printer, Grease Guide29 May 2024

Industrial Lubricants, Grease 3d Printer, Grease Guide29 May 2024 -

Bearing Lubricant - Consolidated Info (& a few questions29 May 2024

Bearing Lubricant - Consolidated Info (& a few questions29 May 2024 -

Markforged Anti Seize Lubricant29 May 2024

-

Sonic Mighty 8K] Cleaning the Z-axis – Phrozen Help Center29 May 2024

-

Is this an ok lube to use for the Z axis rod? I've not been able29 May 2024

Is this an ok lube to use for the Z axis rod? I've not been able29 May 2024 -

Raise3D E2 Desktop 3D Printer - Professional Starter Bundle29 May 2024

Raise3D E2 Desktop 3D Printer - Professional Starter Bundle29 May 2024

You may also like

-

The Walking Dead Poster Season 7 (Exclusive Art) Negan Glenn Abraham - NEW29 May 2024

The Walking Dead Poster Season 7 (Exclusive Art) Negan Glenn Abraham - NEW29 May 2024 -

Stretch Off White Linen Cotton Blend Fabric Medium Weight 50” Wide By The Yard29 May 2024

Stretch Off White Linen Cotton Blend Fabric Medium Weight 50” Wide By The Yard29 May 2024 -

Essential Oil Set, Top 5 - 100% Pure Essential Oils for Diffusers - Pe – UpNature29 May 2024

Essential Oil Set, Top 5 - 100% Pure Essential Oils for Diffusers - Pe – UpNature29 May 2024 -

Muc-Off No Puncture Hassle Tire Sealant - Airborne Bicycles29 May 2024

Muc-Off No Puncture Hassle Tire Sealant - Airborne Bicycles29 May 2024 -

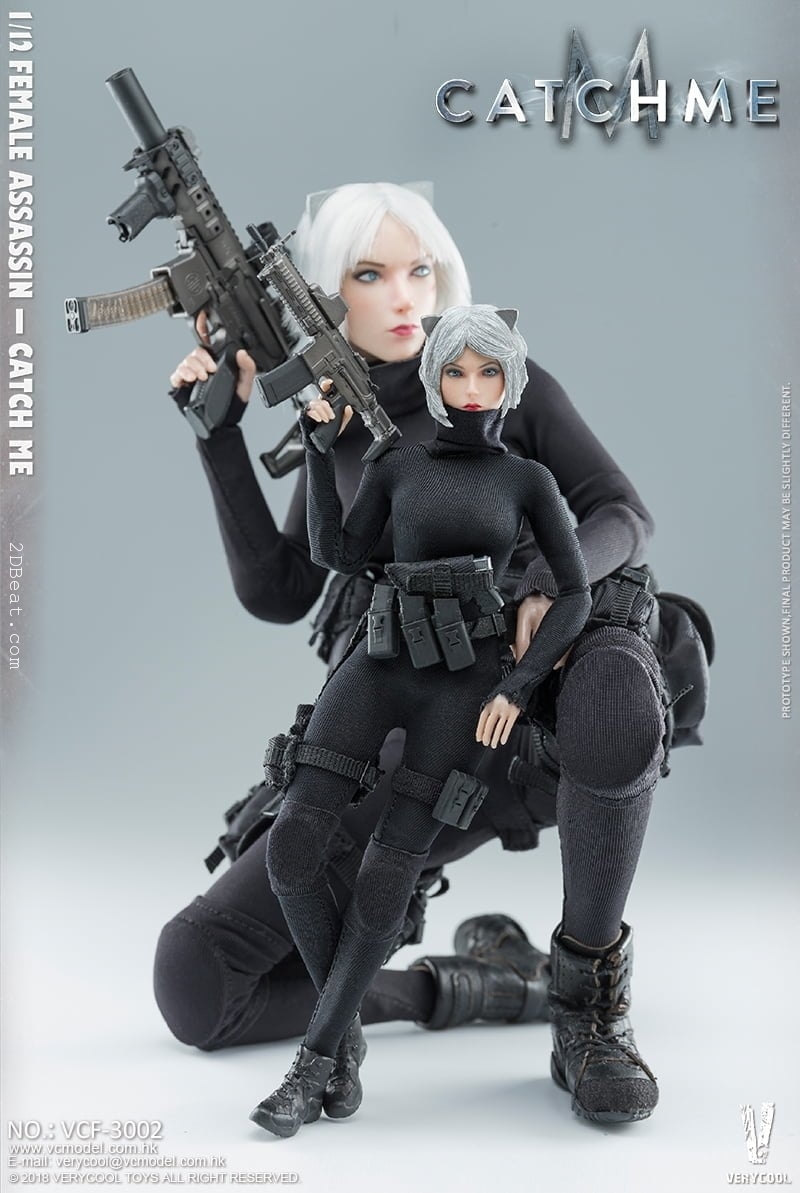

1/12 Scale VERY COOL Female Assassin Catch Me Palm Treasure Series Action Figure29 May 2024

1/12 Scale VERY COOL Female Assassin Catch Me Palm Treasure Series Action Figure29 May 2024 -

OLYCRAFT 10 Sheets Cork Sheets 12x6.1 Inch Thin Cork Roll 1mm Thick Brown Cork Board Rectangle Cork Tiles Cork Mats for Coaster Placemat Kitchen Dining Hall DIY Crafts Supplies29 May 2024

OLYCRAFT 10 Sheets Cork Sheets 12x6.1 Inch Thin Cork Roll 1mm Thick Brown Cork Board Rectangle Cork Tiles Cork Mats for Coaster Placemat Kitchen Dining Hall DIY Crafts Supplies29 May 2024 -

Real number - Wikipedia29 May 2024

Real number - Wikipedia29 May 2024 -

Gifts for Girlfriend: Cute GF Gift Ideas for 202429 May 2024

Gifts for Girlfriend: Cute GF Gift Ideas for 202429 May 2024 -

Accessories Rope Jewellery Making Tool Set Repair Set Kit With Silver Beading Wire Nylon Cord Connecting Rings Metal Bracelet Making Kit29 May 2024

Accessories Rope Jewellery Making Tool Set Repair Set Kit With Silver Beading Wire Nylon Cord Connecting Rings Metal Bracelet Making Kit29 May 2024 -

Combined Brands Five Nights at Freddys Birthday Party Photo Booth29 May 2024

Combined Brands Five Nights at Freddys Birthday Party Photo Booth29 May 2024