Smooth-On Reoflex™ Series

By A Mystery Man Writer

Last updated 16 May 2024

lt;p><strong>ReoFlex™</strong> urethane rubbers offer superior physical and performance properties for production casting of wax, plasters, and resins. <strong>ReoFlex™</strong> urethanes are available in 20A, 30A, 40A, 50A and 60A Shore hardnesses and feature convenient one-to-one by volume mix ratios. Vacuum degassing is not necessary and <strong>ReoFlex™</strong> rubbers cure with negligible shrinkage to a durable rubber that will last in production. <strong>ReoFlex™</strong> “Wet” rubbers will shrink somewhat over time vs. “Dry” formulations.</p> <p></p> <p><strong>ReoFlex™</strong> mold rubbers are used for a variety of applications including making molds to reproduce sculpture and architectural elements, as well as for making special effects, toys and prototypes. Vibrant colors can be achieved by adding <strong>So-Strong™</strong> Color Tints, available from Smooth-On.</p> <p>Casting Concrete? Look into the <strong>VytaFlex™</strong> series of urethane mold rubbers. <strong>VytaFlex™</strong> urethanes were formulated specifically for casting concrete / pigmented concrete and feature Smooth-On’s exclusive ‘V-Polymer™’ technology.</p> <p>Instructions</p> <p><strong>Preparation -</strong> Store and use at room temperature (73°F/23°C). Environmental humidity should be as low as possible. Good ventilation (room size) is necessary. This product has a limited shelf life and should be used as soon as possible. Wear safety glasses, long sleeves and rubber gloves to minimize contamination risk.</p> <p><strong>Some Materials Must Be Sealed -</strong> To prevent adhesion between the rubber and model surface, models made of porous materials (gypsum plasters, concrete, wood, stone, etc.) must be sealed prior to applying a release agent. <strong>SuperSeal™</strong> or <strong>One Step™</strong> (available from Smooth-On) is a fast drying sealer suitable for sealing porous surfaces without interfering with surface detail. <strong>Sonite™ Wax</strong> or shellac is suitable for rough contours. A high quality shellac is suitable for sealing modeling clays that contain sulfur or moisture (water based). Thermoplastics (polystyrene) must also be sealed with shellac or PVA. In all cases, the sealing agent should be applied and allowed to completely dry prior to applying a release agent.</p> <p><strong>Non-Porous Surfaces -</strong> Metal, glass, hard plastics, sulfur free clays, etc. require only a release agent.</p> <p><strong>Applying A Release Agent -</strong> A release agent is necessary to facilitate demolding when casting into or over most surfaces. Use a release agent made specifically for mold making (<strong>Universal™ Mold Release</strong> available from Smooth-On). A liberal coat of release agent should be applied onto all surfaces that will contact the rubber.</p> <p><strong>IMPORTANT:</strong> To ensure thorough coverage, lightly brush the release agent with a soft brush over all surfaces of the model. Follow with a light mist coating and let the release agent dry for 30 minutes.</p> <p><strong>Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.</strong></p> <p><strong>IMPORTANT:</strong> Shelf life of product is reduced after opening. Remaining product should be used as soon as possible. Immediately replacing the lids on both containers after dispensing product will help prolong the shelf life of the unused product. <strong>XTEND-IT™ Dry Gas Blanket</strong> (available from Smooth-On) will significantly prolong the shelf life of unused liquid urethane products.</p> <p><strong>MEASURING & MIXING -</strong> Liquid urethanes are moisture sensitive and will absorb atmospheric moisture. Mixing tools and containers should be clean and made of metal or plastic. Materials should be stored and used in a warm environment (73°F/23°C).</p> <p><strong>IMPORTANT: Pre Mix the Part B before using.</strong> After dispensing equal amounts of Parts A and B into mixing container, mix thoroughly for at least 3 minutes making sure that you scrape the sides and bottom of the mixing container several times.</p> <p><strong>If Mixing Large Quantities</strong> (16 lbs./7 kgs. or more) at one time, use a mechanical mixer (i.e. Squirrel Mixer or equal) for 3 minutes followed by careful hand mixing for one minute as directed above. Then, pour entire quantity into a new, clean mixing container and do it all over again.</p> <p>Although this product is formulated to minimize air bubbles in your the cured rubber, vacuum degassing prior to pouring rubber will further reduce entrapped air.</p> <p><strong>For best results,</strong> pour your mixture in a single spot at the lowest point of the containment field. Let the rubber seek its level up and over the model. <strong>A uniform flow will help minimize entrapped air.</strong> The liquid rubber should level off at least 1/2” (1.3 cm) over the highest point of the model surface.</p> <p><strong>Curing -</strong> Allow rubber to cure overnight (at least 16 hours) at room temperature (73°F/23°C) before demolding. Cure time can be reduced with mild heat or by adding Smooth-On <strong>Kick-It™ Cure Accelerator.</strong> Do not cure rubber where temperature is less than 65°F/18°C.</p> <p><strong>Post Curing -</strong> Optional: Following an overnight cure, heating the rubber to 150°F (65°C) for 4 to 8 hours will increase physical properties and performance.</p> <p><strong>Using The Mold -</strong> If using as a mold material, a release agent should be applied to the mold before each casting. The type of release agent to use depends on the material being cast. The proper release agent for wax, liquid rubber or thermosetting materials (i.e. SmoothOn liquid plastics) is a spray release made specifically for mold making (available from Smooth-On or your distributor. Prior to casting gypsum plaster materials, sponge the mold with a soap solution for better plaster flow and easy release.</p> <p><strong>Performance & Storage -</strong> Fully cured rubber is tough, durable and will perform if properly used and stored. The physical life of the rubber depends on how you use it.</p> <p> </p> <p></p> <p></p> <p></p> <p></p> <p></p>

ReoFlex™ urethane rubbers offer superior physical and performance properties for production casting of wax, plasters, and resins. ReoFlex™ urethanes are available in 20A, 30A, 40A, 50A and 60A Shore hardnesses and feature convenient one-to-one by volume mix ratios. Vacuum degassing is not necessary and ReoFlex™ rubbers cure with negligible shrinkage to a durable rubber that will last in production. ReoFlex™ “Wet” rubbers will shrink somewhat over time vs. “Dry” formulations. ReoFlex™ mold rubbers are used for a variety of applications including making molds to reproduce sculpture and architectural elements, as well as for making special effects, toys and prototypes. Vibrant colors can be achieved by adding So-Strong™ Color Tints, available from Smooth-On. Casting Concrete? Look into the VytaFlex™ series of urethane mold rubbers. VytaFlex™ urethanes were formulated specifically for casting concrete / pigmented concrete and feature Smooth-On’s exclusive ‘V-Polymer™’ technology. Instructions Preparation - Store and use at room temperature (73°F/23°C). Environmental humidity should be as low as possible. Good ventilation (room size) is necessary. This product has a limited shelf life and should be used as soon as possible. Wear safety glasses, long sleeves and rubber gloves to minimize contamination risk. Some Materials Must Be Sealed - To prevent adhesion between the rubber and model surface, models made of porous materials (gypsum plasters, concrete, wood, stone, etc.) must be sealed prior to applying a release agent. SuperSeal™ or One Step™ (available from Smooth-On) is a fast drying sealer suitable for sealing porous surfaces without interfering with surface detail. Sonite™ Wax or shellac is suitable for rough contours. A high quality shellac is suitable for sealing modeling clays that contain sulfur or moisture (water based). Thermoplastics (polystyrene) must also be sealed with shellac or PVA. In all cases, the sealing agent should be applied and allowed to completely dry prior to applying a release agent. Non-Porous Surfaces - Metal, glass, hard plastics, sulfur free clays, etc. require only a release agent. Applying A Release Agent - A release agent is necessary to facilitate demolding when casting into or over most surfaces. Use a release agent made specifically for mold making (Universal™ Mold Release available from Smooth-On). A liberal coat of release agent should be applied onto all surfaces that will contact the rubber. IMPORTANT: To ensure thorough coverage, lightly brush the release agent with a soft brush over all surfaces of the model. Follow with a light mist coating and let the release agent dry for 30 minutes. Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question. IMPORTANT: Shelf life of product is reduced after opening. Remaining product should be used as soon as possible. Immediately replacing the lids on both containers after dispensing product will help prolong the shelf life of the unused product. XTEND-IT™ Dry Gas Blanket (available from Smooth-On) will significantly prolong the shelf life of unused liquid urethane products. MEASURING & MIXING - Liquid urethanes are moisture sensitive and will absorb atmospheric moisture. Mixing tools and containers should be clean and made of metal or plastic. Materials should be stored and used in a warm environment (73°F/23°C). IMPORTANT: Pre Mix the Part B before using. After dispensing equal amounts of Parts A and B into mixing container, mix thoroughly for at least 3 minutes making sure that you scrape the sides and bottom of the mixing container several times. If Mixing Large Quantities (16 lbs./7 kgs. or more) at one time, use a mechanical mixer (i.e. Squirrel Mixer or equal) for 3 minutes followed by careful hand mixing for one minute as directed above. Then, pour entire quantity into a new, clean mixing container and do it all over again. Although this product is formulated to minimize air bubbles in your the cured rubber, vacuum degassing prior to pouring rubber will further reduce entrapped air. For best results, pour your mixture in a single spot at the lowest point of the containment field. Let the rubber seek its level up and over the model. A uniform flow will help minimize entrapped air. The liquid rubber should level off at least 1/2” (1.3 cm) over the highest point of the model surface. Curing - Allow rubber to cure overnight (at least 16 hours) at room temperature (73°F/23°C) before demolding. Cure time can be reduced with mild heat or by adding Smooth-On Kick-It™ Cure Accelerator. Do not cure rubber where temperature is less than 65°F/18°C. Post Curing - Optional: Following an overnight cure, heating the rubber to 150°F (65°C) for 4 to 8 hours will increase physical properties and performance. Using The Mold - If using as a mold material, a release agent should be applied to the mold before each casting. The type of release agent to use depends on the material being cast. The proper release agent for wax, liquid rubber or thermosetting materials (i.e. SmoothOn liquid plastics) is a spray release made specifically for mold making (available from Smooth-On or your distributor. Prior to casting gypsum plaster materials, sponge the mold with a soap solution for better plaster flow and easy release. Performance & Storage - Fully cured rubber is tough, durable and will perform if properly used and stored. The physical life of the rubber depends on how you use it.

ReoFlex™ urethane rubbers offer superior physical and performance properties for production casting of wax, plasters, and resins. ReoFlex™ urethanes are available in 20A, 30A, 40A, 50A and 60A Shore hardnesses and feature convenient one-to-one by volume mix ratios. Vacuum degassing is not necessary and ReoFlex™ rubbers cure with negligible shrinkage to a durable rubber that will last in production. ReoFlex™ “Wet” rubbers will shrink somewhat over time vs. “Dry” formulations. ReoFlex™ mold rubbers are used for a variety of applications including making molds to reproduce sculpture and architectural elements, as well as for making special effects, toys and prototypes. Vibrant colors can be achieved by adding So-Strong™ Color Tints, available from Smooth-On. Casting Concrete? Look into the VytaFlex™ series of urethane mold rubbers. VytaFlex™ urethanes were formulated specifically for casting concrete / pigmented concrete and feature Smooth-On’s exclusive ‘V-Polymer™’ technology. Instructions Preparation - Store and use at room temperature (73°F/23°C). Environmental humidity should be as low as possible. Good ventilation (room size) is necessary. This product has a limited shelf life and should be used as soon as possible. Wear safety glasses, long sleeves and rubber gloves to minimize contamination risk. Some Materials Must Be Sealed - To prevent adhesion between the rubber and model surface, models made of porous materials (gypsum plasters, concrete, wood, stone, etc.) must be sealed prior to applying a release agent. SuperSeal™ or One Step™ (available from Smooth-On) is a fast drying sealer suitable for sealing porous surfaces without interfering with surface detail. Sonite™ Wax or shellac is suitable for rough contours. A high quality shellac is suitable for sealing modeling clays that contain sulfur or moisture (water based). Thermoplastics (polystyrene) must also be sealed with shellac or PVA. In all cases, the sealing agent should be applied and allowed to completely dry prior to applying a release agent. Non-Porous Surfaces - Metal, glass, hard plastics, sulfur free clays, etc. require only a release agent. Applying A Release Agent - A release agent is necessary to facilitate demolding when casting into or over most surfaces. Use a release agent made specifically for mold making (Universal™ Mold Release available from Smooth-On). A liberal coat of release agent should be applied onto all surfaces that will contact the rubber. IMPORTANT: To ensure thorough coverage, lightly brush the release agent with a soft brush over all surfaces of the model. Follow with a light mist coating and let the release agent dry for 30 minutes. Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question. IMPORTANT: Shelf life of product is reduced after opening. Remaining product should be used as soon as possible. Immediately replacing the lids on both containers after dispensing product will help prolong the shelf life of the unused product. XTEND-IT™ Dry Gas Blanket (available from Smooth-On) will significantly prolong the shelf life of unused liquid urethane products. MEASURING & MIXING - Liquid urethanes are moisture sensitive and will absorb atmospheric moisture. Mixing tools and containers should be clean and made of metal or plastic. Materials should be stored and used in a warm environment (73°F/23°C). IMPORTANT: Pre Mix the Part B before using. After dispensing equal amounts of Parts A and B into mixing container, mix thoroughly for at least 3 minutes making sure that you scrape the sides and bottom of the mixing container several times. If Mixing Large Quantities (16 lbs./7 kgs. or more) at one time, use a mechanical mixer (i.e. Squirrel Mixer or equal) for 3 minutes followed by careful hand mixing for one minute as directed above. Then, pour entire quantity into a new, clean mixing container and do it all over again. Although this product is formulated to minimize air bubbles in your the cured rubber, vacuum degassing prior to pouring rubber will further reduce entrapped air. For best results, pour your mixture in a single spot at the lowest point of the containment field. Let the rubber seek its level up and over the model. A uniform flow will help minimize entrapped air. The liquid rubber should level off at least 1/2” (1.3 cm) over the highest point of the model surface. Curing - Allow rubber to cure overnight (at least 16 hours) at room temperature (73°F/23°C) before demolding. Cure time can be reduced with mild heat or by adding Smooth-On Kick-It™ Cure Accelerator. Do not cure rubber where temperature is less than 65°F/18°C. Post Curing - Optional: Following an overnight cure, heating the rubber to 150°F (65°C) for 4 to 8 hours will increase physical properties and performance. Using The Mold - If using as a mold material, a release agent should be applied to the mold before each casting. The type of release agent to use depends on the material being cast. The proper release agent for wax, liquid rubber or thermosetting materials (i.e. SmoothOn liquid plastics) is a spray release made specifically for mold making (available from Smooth-On or your distributor. Prior to casting gypsum plaster materials, sponge the mold with a soap solution for better plaster flow and easy release. Performance & Storage - Fully cured rubber is tough, durable and will perform if properly used and stored. The physical life of the rubber depends on how you use it.

Materials Shelf Life Warranty

Smooth-On Pmc 121 Series

Smooth-On Sorta-Clear™ 40

Urethane Rubber Accessories, Take Your Urethane Rubber Further

ReoFlex Series Available in the US and Canada - Reynolds Advanced

SO-FLEX II Pint - The Compleat Sculptor

Smooth-On Brush-On™ 60

Singer Exclusive Survival Sew Kit 70/Pkg

Blackjack Low Fire Clay™ Natural Kiln Earthenware, 20 Lb (9.07 Kg)

Smooth-On BLICK Art Materials

ReoFlex™ 50 Product Information

Smooth-On Kick-iT!™ Urethane Rubber Cure Accelerator is an additive designed to “accelerate” the cure time of Smooth-On VytaFlex™, ReoFlex™ and PMC™

Smooth-On Kick-iT!™ Accelerator

Smooth-On Brush-On™ 50

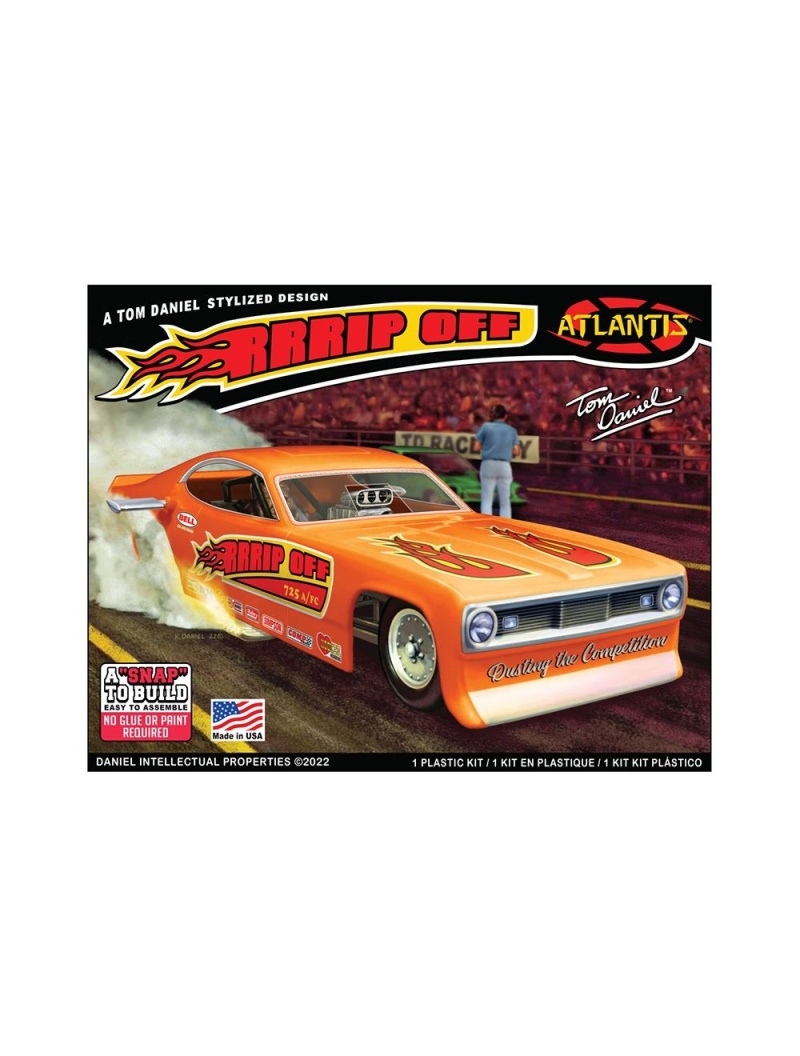

Atlantis Plastic Model Kit-Snap Tom Daniel Rrrrip Off Funny Car

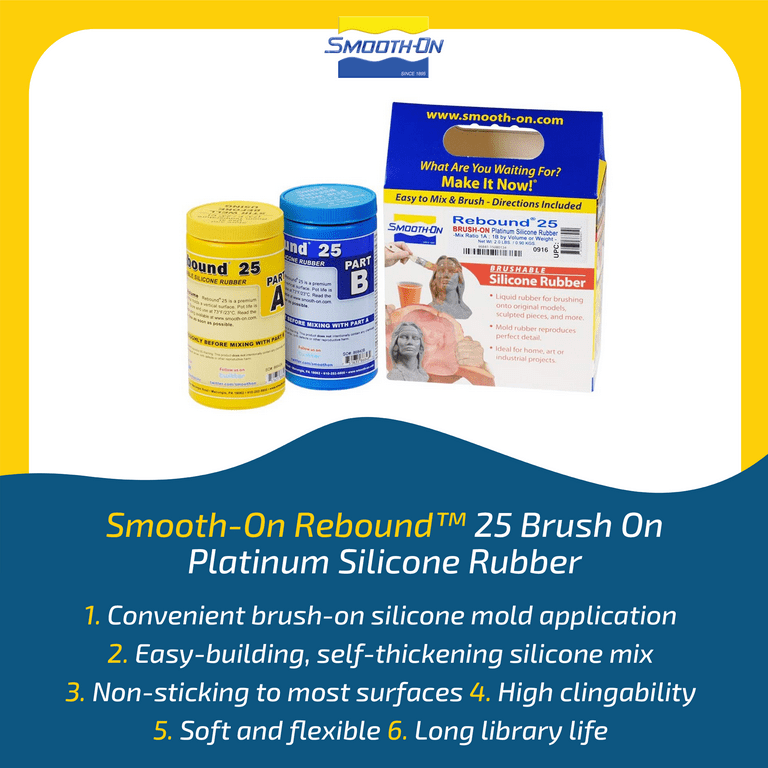

Smooth-On Rebound™ Series

Recommended for you

-

Mold Star™ Series, Easy to Use Silicone Mold Rubber16 May 2024

Mold Star™ Series, Easy to Use Silicone Mold Rubber16 May 2024 -

Smooth-On Silicone Mold Making Rubber16 May 2024

Smooth-On Silicone Mold Making Rubber16 May 2024 -

Smooth-On Rebound 25 Silicone Rubber16 May 2024

Smooth-On Rebound 25 Silicone Rubber16 May 2024 -

Smooth-On Oomoo Silicone Rubber - OOMOO 2516 May 2024

Smooth-On Oomoo Silicone Rubber - OOMOO 2516 May 2024 -

Smooth On Silicone Skin Tite Adhesive, Jar at Rs 7500/piece in16 May 2024

Smooth On Silicone Skin Tite Adhesive, Jar at Rs 7500/piece in16 May 2024 -

Smooth-On - Silicone - Dragon Skin™ 10 NV - Low Viscosity & High16 May 2024

Smooth-On - Silicone - Dragon Skin™ 10 NV - Low Viscosity & High16 May 2024 -

Textured vs Smooth Implants16 May 2024

Textured vs Smooth Implants16 May 2024 -

Smooth-On Silc Pig Silicone Color Pigment - Red, 4 oz16 May 2024

Smooth-On Silc Pig Silicone Color Pigment - Red, 4 oz16 May 2024 -

Smooth On Silicone Skin Tite Adhesive, Jar at Rs 7500/piece in Mumbai16 May 2024

Smooth On Silicone Skin Tite Adhesive, Jar at Rs 7500/piece in Mumbai16 May 2024 -

Smooth-On Rebound™ Series16 May 2024

Smooth-On Rebound™ Series16 May 2024

You may also like

-

10 pcs Finger Thimble Protector Sewing Pin Needle Metal Thimble 6E7R Sale O7X316 May 2024

10 pcs Finger Thimble Protector Sewing Pin Needle Metal Thimble 6E7R Sale O7X316 May 2024 -

Scotch-Weld rigid Epoxy dp270clear two-part epoxy adhesive16 May 2024

Scotch-Weld rigid Epoxy dp270clear two-part epoxy adhesive16 May 2024 -

Pressed Dried Flowers 20pcs, Small Pressed Yellow Flower Set, Dried Flower Mix for Crafts16 May 2024

Pressed Dried Flowers 20pcs, Small Pressed Yellow Flower Set, Dried Flower Mix for Crafts16 May 2024 -

lzd-img-global.slatic.net/g/p/47cebc1cdaf2efdc289916 May 2024

lzd-img-global.slatic.net/g/p/47cebc1cdaf2efdc289916 May 2024 -

Otto Brights PVC Tube Pencil Case White16 May 2024

Otto Brights PVC Tube Pencil Case White16 May 2024 -

8/12 Colors Water Painting Pen Kids Drawing Markers Brushes Set Supplies Oil - Paint By Number Pens & Brushes - Aliexpress16 May 2024

8/12 Colors Water Painting Pen Kids Drawing Markers Brushes Set Supplies Oil - Paint By Number Pens & Brushes - Aliexpress16 May 2024 -

Clairefontaine Pastelmat Paper16 May 2024

Clairefontaine Pastelmat Paper16 May 2024 -

Huilaibazo Slim Fit Jumpsuit Women V Neck Dressy Romper Classy Wide Leg Playsuit Sexy Casual Strappy Waist Up Romper Pants16 May 2024

Huilaibazo Slim Fit Jumpsuit Women V Neck Dressy Romper Classy Wide Leg Playsuit Sexy Casual Strappy Waist Up Romper Pants16 May 2024 -

12 Pieces Cute Box Cutter Utility Retractable Knives, 6 Cartoon16 May 2024

12 Pieces Cute Box Cutter Utility Retractable Knives, 6 Cartoon16 May 2024 -

Air Locker A04 Manual Metal Slot Punch Plier T-shaped Hole Cutting Tool Hanger Hole Punch, Punch Out Dimension: 1 x 5/1616 May 2024

Air Locker A04 Manual Metal Slot Punch Plier T-shaped Hole Cutting Tool Hanger Hole Punch, Punch Out Dimension: 1 x 5/1616 May 2024