Music Wire Spring Material Manufacturing for Corrosive Environments Applications

By A Mystery Man Writer

Last updated 15 Jun 2024

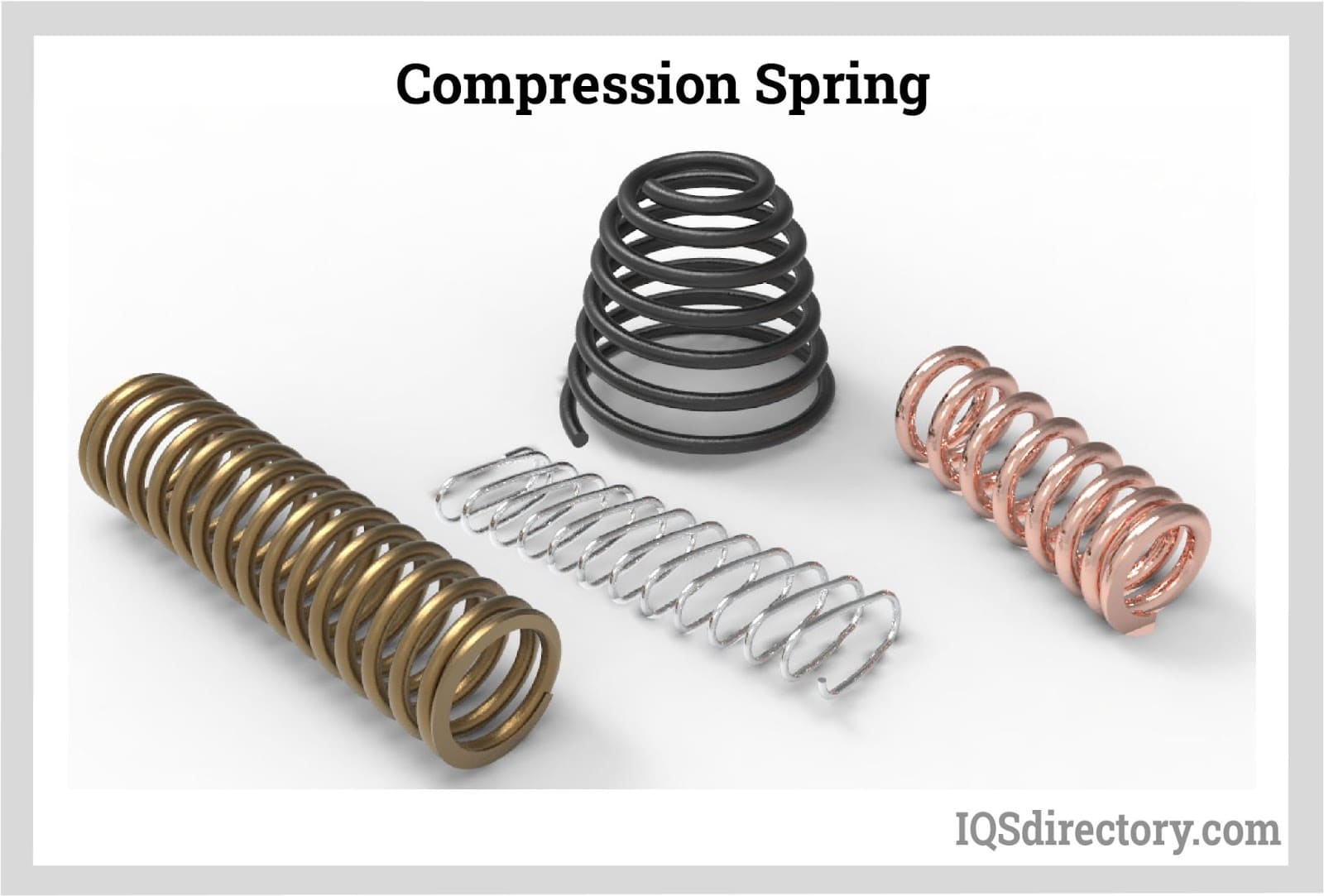

Custom Spring Wire Manufacturer and Supplier in China-Compression Spring Wire

Music Wire Extension Spring, Steel, Inch, 0.75 OD, 0.125 Wire Size, 4 Free Length, 5.22 Extended Length, 87.94 lbs Load Capacity, 65.3 lbs/in Spring Rate (Pack of 10): : Industrial & Scientific

Highly magnetic steel music wire for greater strength than stainless steel or copper wire Spring ends are closed and ground flat (squared) for

Music Wire Compression Spring, Steel, Inch, 0.24 OD, 0.04 Wire Size, 0.233 Compressed Length, 0.31 Free Length, 12.03 lbs Load Capacity, 155.8

: Industrial & Scientific

Music Wire Compression Spring, Steel, Inch, 0.24 OD, 0.04 Wire Size, 0.233 Compressed Length, 0.31 Free Length, 12.03 lbs Load Capacity, 155.8

Music Wire Spring Material Manufacturing for Corrosive Environments Applications

Electrical Conductivity's Impact on Spring Performance — Tevema BV

How Material Affects Spring Longevity - JB Springs

Benefits of Stainless Steel Spring Wire

What Materials are Used for Springs? 21 Common Spring Materials

Compression Spring Materials and Finishes

Compression Springs: Materials, Types, Applications, and Advantages

Highly magnetic steel music wire for greater strength than stainless steel or copper wire Spring ends are closed and ground flat (squared) for

Music Wire Compression Spring, Steel, Metric, 14 mm OD, 2.8 mm Wire Size, 22.3 mm Compressed Length, 29 mm Free Length, 518.75 N Load Capacity, 62.86

Custom Medical Coils - Western Spring Manufacturing

5 Manufacturing Mistakes That Cause Spring Problems - KB Delta

Recommended for you

-

Precision Brand 21031 Music Wire, Steel Alloy, 0.031 in15 Jun 2024

Precision Brand 21031 Music Wire, Steel Alloy, 0.031 in15 Jun 2024 -

BrassCraft 5/16-in dia x 25-ft L Music Wire Machine Auger in the Machine Augers department at15 Jun 2024

BrassCraft 5/16-in dia x 25-ft L Music Wire Machine Auger in the Machine Augers department at15 Jun 2024 -

Stainless Steel Wire - MSC Industrial Supply15 Jun 2024

Stainless Steel Wire - MSC Industrial Supply15 Jun 2024 -

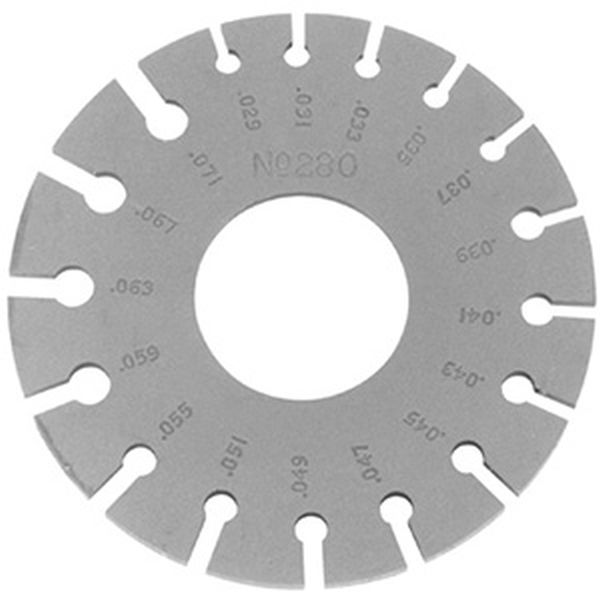

Piano String & Music Wire Gauge15 Jun 2024

Piano String & Music Wire Gauge15 Jun 2024 -

New Piano Music Wire - For Replacement of Broken15 Jun 2024

New Piano Music Wire - For Replacement of Broken15 Jun 2024 -

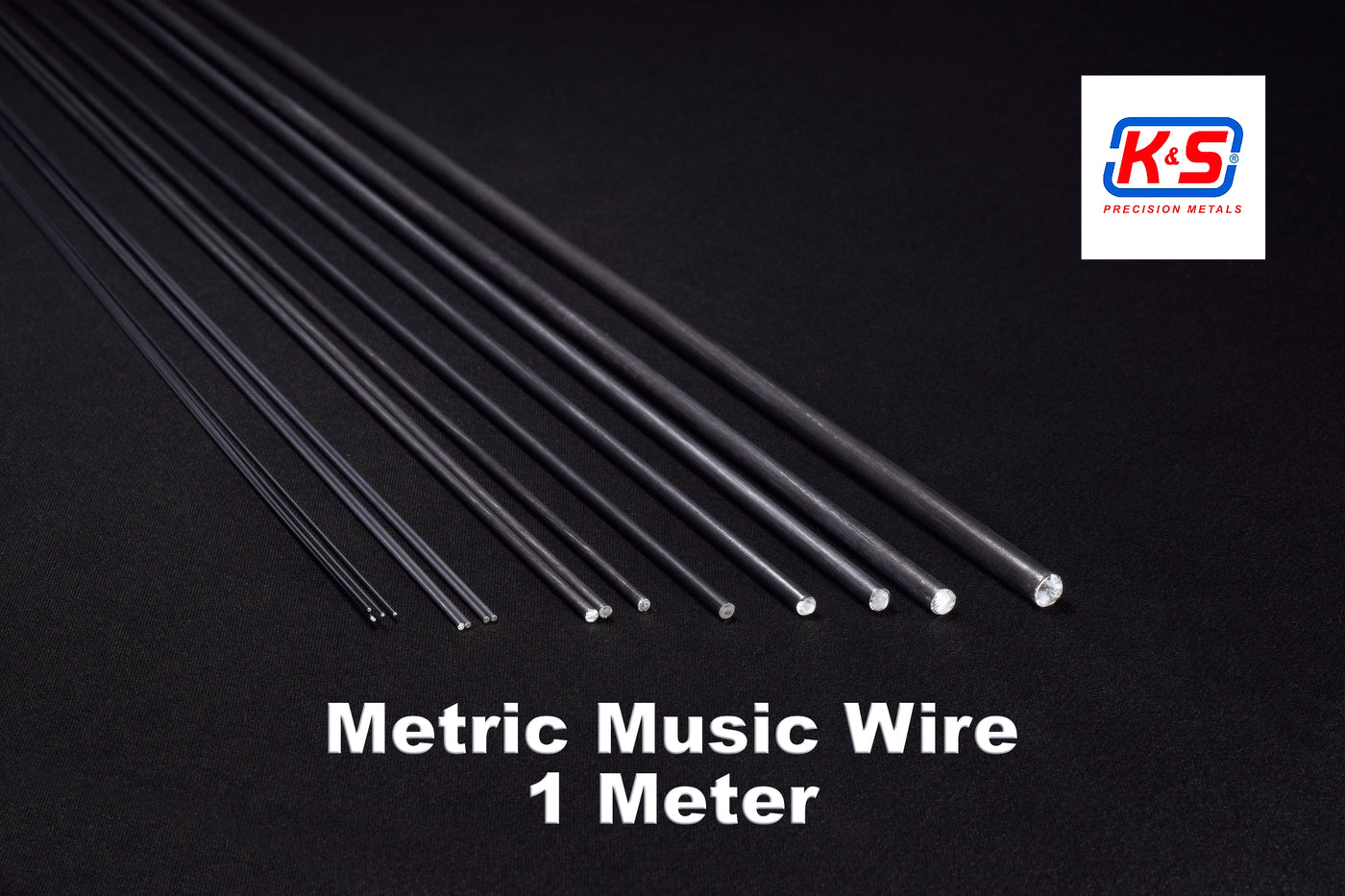

K&S 2.5mm Steel Music Wire15 Jun 2024

K&S 2.5mm Steel Music Wire15 Jun 2024 -

Precision Brand 29062 Music Wire,Type 302 SS,0.0625 in15 Jun 2024

-

Compression Spring - 0.36 OD x .042 Wire Dia. - Music Wire - Zinc15 Jun 2024

Compression Spring - 0.36 OD x .042 Wire Dia. - Music Wire - Zinc15 Jun 2024 -

Value Collection - 5 Gage, 0.014 Inch Diameter x 478 Ft. Long15 Jun 2024

Value Collection - 5 Gage, 0.014 Inch Diameter x 478 Ft. Long15 Jun 2024 -

Piano Music Wire/String choose size/gauge 13 - .031 length 1015 Jun 2024

Piano Music Wire/String choose size/gauge 13 - .031 length 1015 Jun 2024

You may also like

-

6 Art Stone Molds Combo Silicone Happy Dotting Company15 Jun 2024

6 Art Stone Molds Combo Silicone Happy Dotting Company15 Jun 2024 -

Couples, Signature Art Print15 Jun 2024

Couples, Signature Art Print15 Jun 2024 -

Things To Keep Toddler Busy On Plane15 Jun 2024

Things To Keep Toddler Busy On Plane15 Jun 2024 -

Golden Confetti on Pastel Pink Background, Party Gold Glitter Backdrop. Stock Photo by JuliaManga15 Jun 2024

Golden Confetti on Pastel Pink Background, Party Gold Glitter Backdrop. Stock Photo by JuliaManga15 Jun 2024 -

Trophy Skin BrightenMD 4-in-1 Device15 Jun 2024

Trophy Skin BrightenMD 4-in-1 Device15 Jun 2024 -

Htv Heat Transfer Vinyl Bundle Sheets Iron On Vinyl 7 - Temu15 Jun 2024

Htv Heat Transfer Vinyl Bundle Sheets Iron On Vinyl 7 - Temu15 Jun 2024 -

Zep Foaming Glass and Plexiglass Cleaner - 19 Ounces (Case of 4) ZUFGC19 - Foaming Formula Clings to Vertical Surfaces. Trusted by Pros : Health & Household15 Jun 2024

Zep Foaming Glass and Plexiglass Cleaner - 19 Ounces (Case of 4) ZUFGC19 - Foaming Formula Clings to Vertical Surfaces. Trusted by Pros : Health & Household15 Jun 2024 -

mexican charms for bracelets wholesale|TikTok Search15 Jun 2024

-

Pinch Perfect Tumbler Clamp,Sublimation Tumblers Pinch,for 20 Oz Sublimation Blanks Tumblers Pinch Perfect Clamp For Sublimation Paper And Glass Supplies15 Jun 2024

Pinch Perfect Tumbler Clamp,Sublimation Tumblers Pinch,for 20 Oz Sublimation Blanks Tumblers Pinch Perfect Clamp For Sublimation Paper And Glass Supplies15 Jun 2024 -

Chemical Guys All Clean+ Citrus Based All Purpose Super Cleaner (16oz)15 Jun 2024

Chemical Guys All Clean+ Citrus Based All Purpose Super Cleaner (16oz)15 Jun 2024