Inert Gas Blanketing in Solder Reflow Ovens - Cambridge Sensotec

By A Mystery Man Writer

Last updated 02 Jun 2024

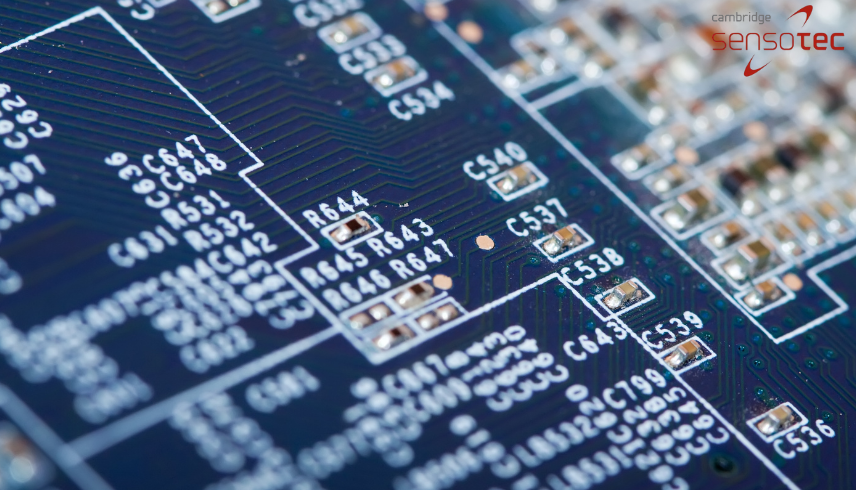

Inert gas blanketing reduces the risk of oxidisation and improves the reliability and product quality throughout the solder reflow process

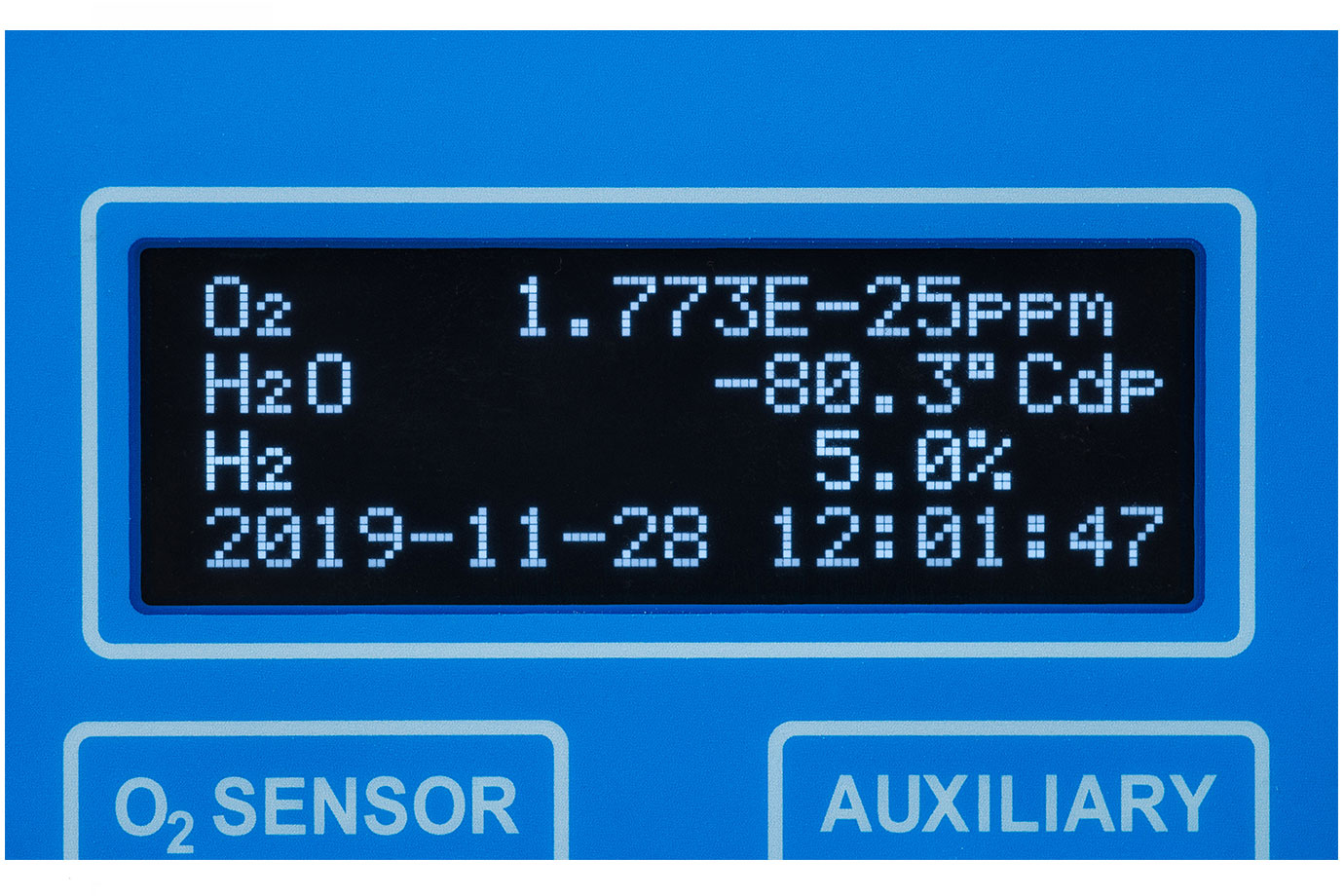

Rapidox 2100-FGA Forming Gas Analyser - Cambridge Sensotec

Rapidox 2112 Multiplex - Cambridge Sensotec

Rapidox 7100 Multigas Analyser

Semiconductor Gas Analysis for Purity

Professional bench-top prototype soldering equipment-old - Eurocircuits

Hydrogen Safety Enhancement with Cambridge Sensotec

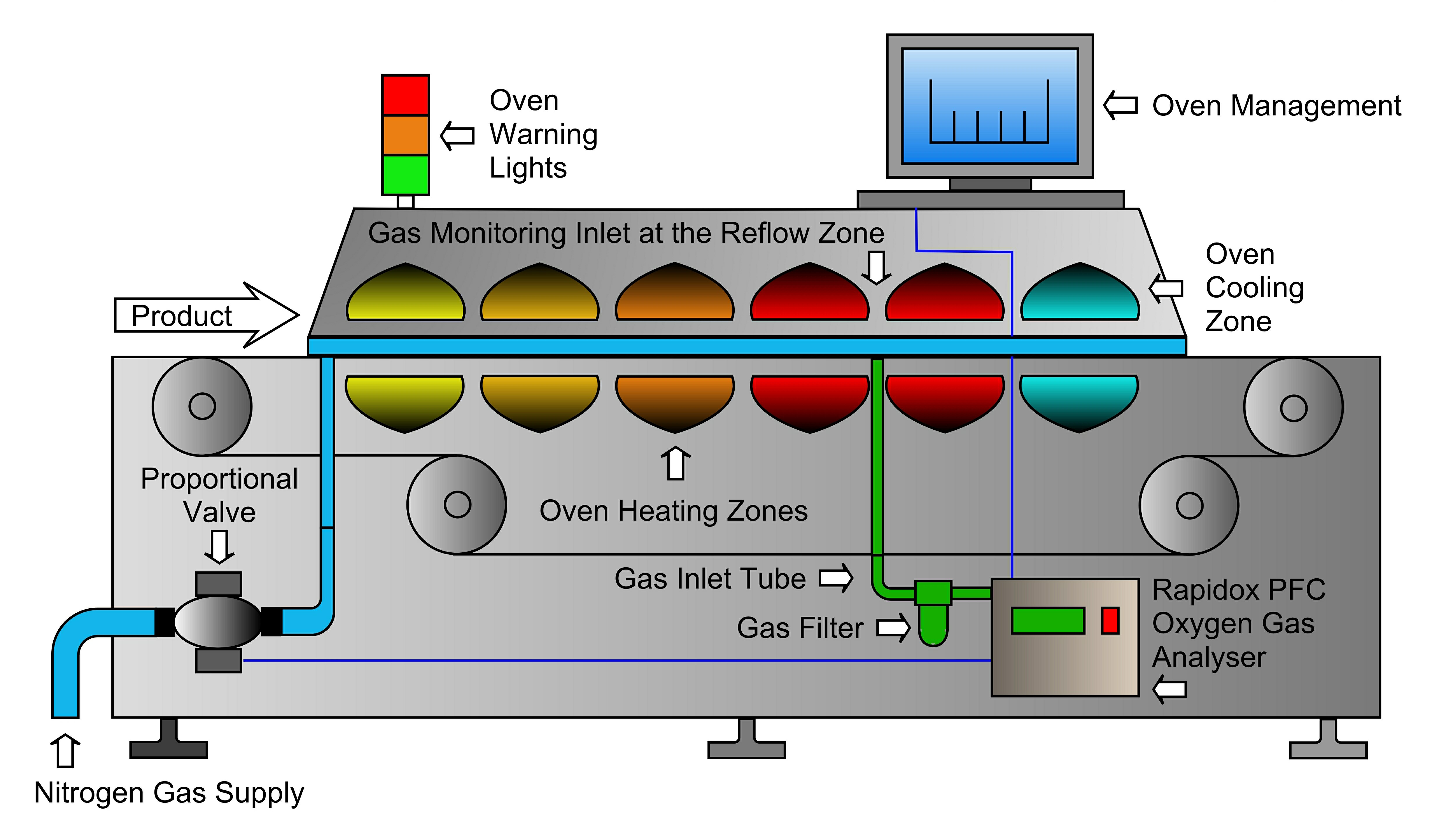

EP1511593B1 - Reflow oven gas management system and method - Google Patents

Single Gas Analyser - Cambridge Sensotec

Hydrogen Gas Analysis for Fuel Cells

Rapidox 7100 Blue Hydrogen Analyser

Gas Measurement in Solder Reflow Ovens

Cambridge Sensotec's PFC System in Heller Solder Reflow Ovens

Recommended for you

-

Reflow oven - Wikipedia02 Jun 2024

Reflow oven - Wikipedia02 Jun 2024 -

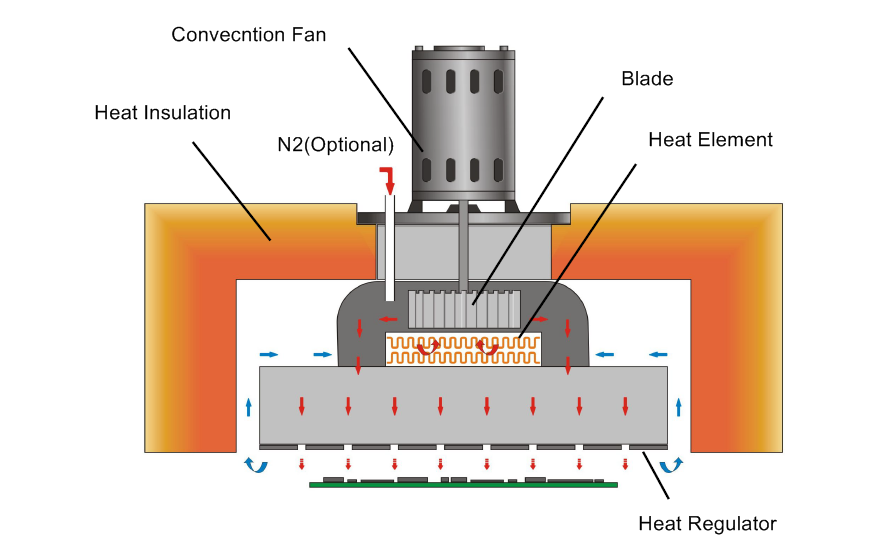

How the modern solder reflow oven works? - Bittele02 Jun 2024

How the modern solder reflow oven works? - Bittele02 Jun 2024 -

PUHUI Reflow Oven Reflow Soldering Machine T962A SMD BGA Infrared IC Heater02 Jun 2024

PUHUI Reflow Oven Reflow Soldering Machine T962A SMD BGA Infrared IC Heater02 Jun 2024 -

Nitrogen PCB Reflow Oven for SMT Solder Reflow Machine from China manufacturer - I.C.T SMT Machine02 Jun 2024

Nitrogen PCB Reflow Oven for SMT Solder Reflow Machine from China manufacturer - I.C.T SMT Machine02 Jun 2024 -

I'm Building a Reflow Oven!02 Jun 2024

I'm Building a Reflow Oven!02 Jun 2024 -

I.C.T-L12 Customized 12 Zones Reflow Soldering Oven LED Nitrogen Reflow Oven from China manufacturer - I.C.T SMT Machine02 Jun 2024

I.C.T-L12 Customized 12 Zones Reflow Soldering Oven LED Nitrogen Reflow Oven from China manufacturer - I.C.T SMT Machine02 Jun 2024 -

NeoDen T-962A Small Mini Reflow Oven Manufacturers and Suppliers China - Wholesale Products - Neoden Technology02 Jun 2024

NeoDen T-962A Small Mini Reflow Oven Manufacturers and Suppliers China - Wholesale Products - Neoden Technology02 Jun 2024 -

CR10000 10-Zone SMT Reflow Oven02 Jun 2024

CR10000 10-Zone SMT Reflow Oven02 Jun 2024 -

Reflow Oven Control with QB1/PSR02 Jun 2024

Reflow Oven Control with QB1/PSR02 Jun 2024 -

ZB2520HL SMT Hot Air Circulation Reflow Oven for IC Chip Reflow Soldering and Welding Oven - AC 220V±10% 1600W, Welding Area 250 x 200mm, max 300℃02 Jun 2024

ZB2520HL SMT Hot Air Circulation Reflow Oven for IC Chip Reflow Soldering and Welding Oven - AC 220V±10% 1600W, Welding Area 250 x 200mm, max 300℃02 Jun 2024

You may also like

-

DAS Ceramic Air Hardening Dry Modelling Clay Dough Pulp Material DIY Equipment 500 Gr White Terra Cotta Brown02 Jun 2024

DAS Ceramic Air Hardening Dry Modelling Clay Dough Pulp Material DIY Equipment 500 Gr White Terra Cotta Brown02 Jun 2024 -

Himalaya Party Smart Capsules at Rs 90/pack02 Jun 2024

Himalaya Party Smart Capsules at Rs 90/pack02 Jun 2024 -

WHITE FLORAL WIRE GAUGE 18MM. SET 20 PCS., THICKNESS 1,2MM CULPITT ( 13802 Jun 2024

WHITE FLORAL WIRE GAUGE 18MM. SET 20 PCS., THICKNESS 1,2MM CULPITT ( 13802 Jun 2024 -

Raised Spot UV Hang Tags02 Jun 2024

Raised Spot UV Hang Tags02 Jun 2024 -

Homemade Dawn Powerwash Spray Solution, Money Saving Tips02 Jun 2024

Homemade Dawn Powerwash Spray Solution, Money Saving Tips02 Jun 2024 -

100 Thick Kraft Chipboard (30pt) - 8 1/2 x 1102 Jun 2024

100 Thick Kraft Chipboard (30pt) - 8 1/2 x 1102 Jun 2024 -

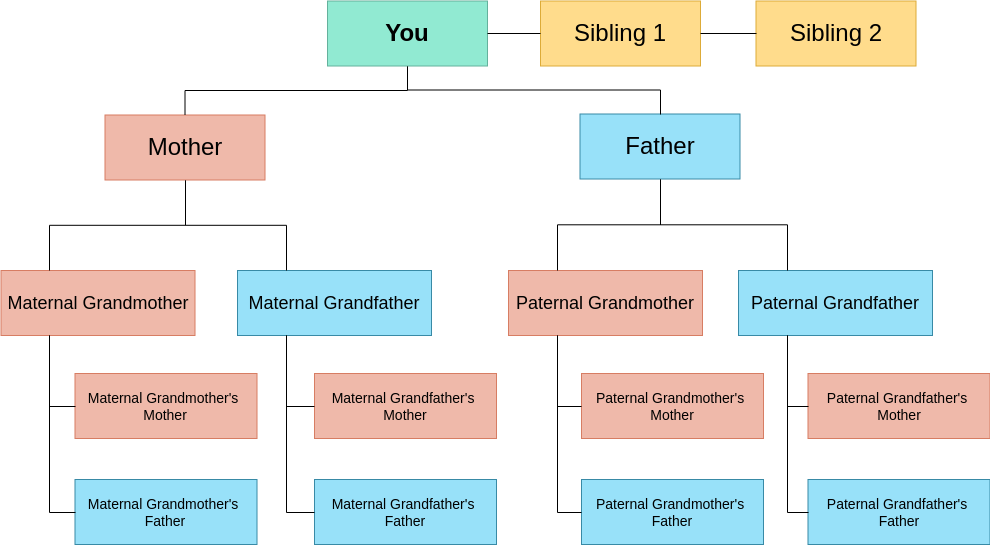

Simple Family Tree Family Tree Template02 Jun 2024

Simple Family Tree Family Tree Template02 Jun 2024 -

CRC Silicone industrial 500ml02 Jun 2024

CRC Silicone industrial 500ml02 Jun 2024 -

MONTEGRAPPA HARRY POTTER HOGWARTS SILVER Ltd EDITION FOUNTAIN PEN – Exceptional Objects02 Jun 2024

MONTEGRAPPA HARRY POTTER HOGWARTS SILVER Ltd EDITION FOUNTAIN PEN – Exceptional Objects02 Jun 2024 -

Marie Antoinette – extravagant French queen has long been a symbol02 Jun 2024

Marie Antoinette – extravagant French queen has long been a symbol02 Jun 2024